Visual preview:

I live in Chacewater = local.

My Career directory . Some links there duplicate specific cases presented here.

I design applying

Examples...

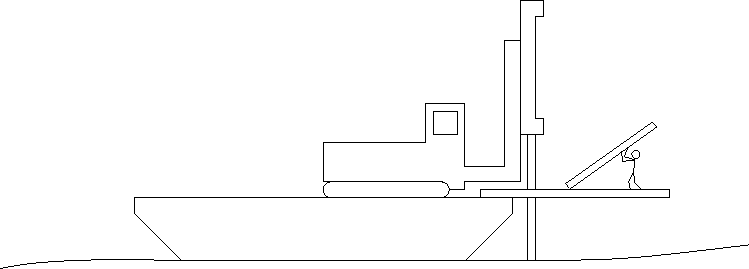

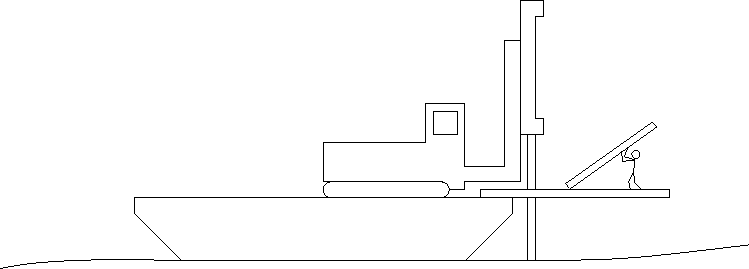

Cantilever drilling platform - analysis using beam calculations

Visual preview:

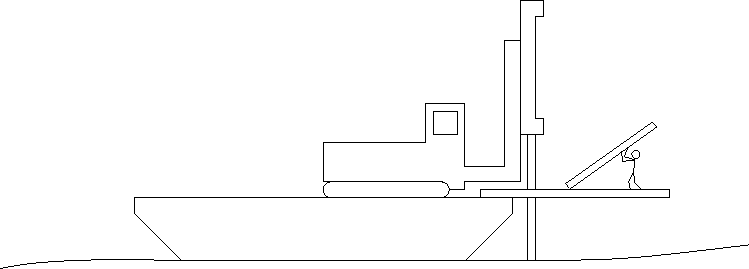

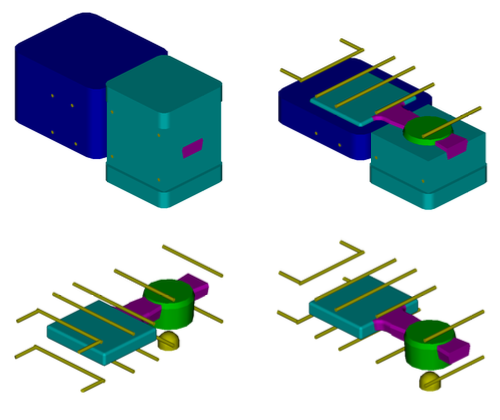

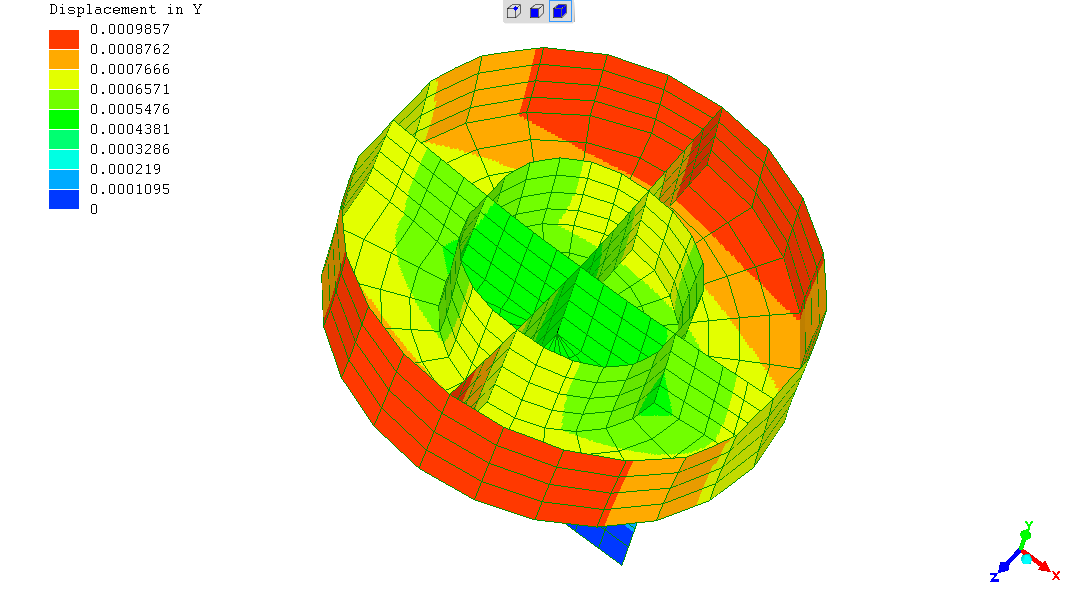

Hydraulic inner fatigue test - piston stiffness - FEA models

Visual preview:

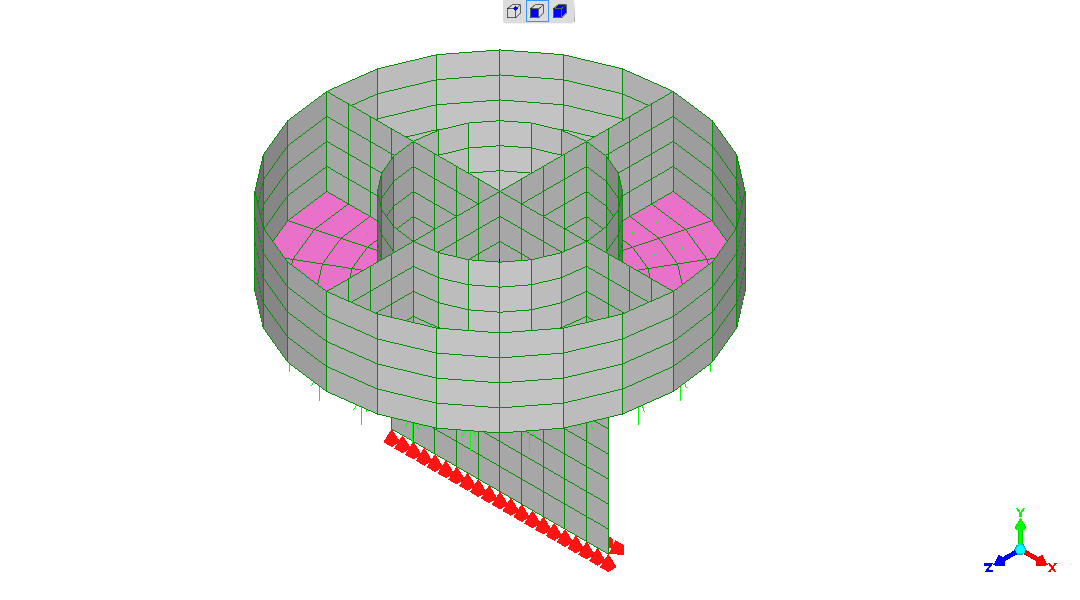

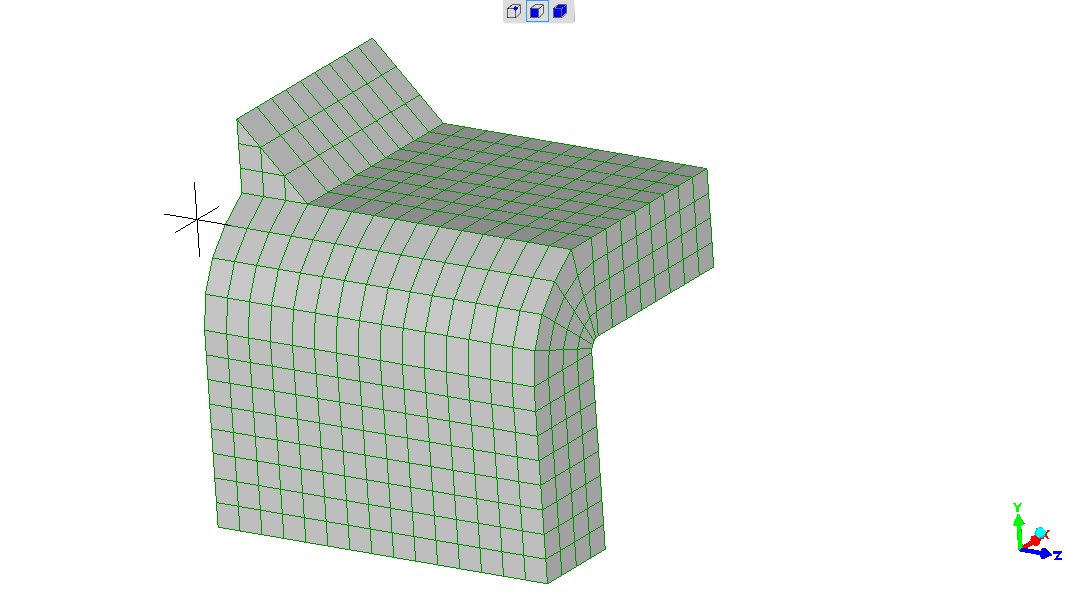

FEA3D : BCFWTT RHS beam top surface around test weld

Visual preview:

Rectangular Hollow Section beam calculator

[is coded in server-side scripting language "PHP" - gets my webhost's

computer to do calculation and send answer back to you as a simple

HTML page]

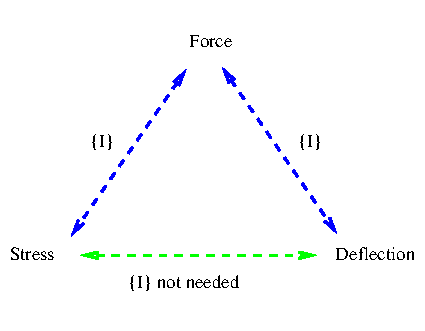

Euler-Bernoulli beam stress-vs-deflection equations

Visual preview:

My engineering skills come out of welding & construction; that following from pursuing training as a scientist resulting from working in the steel industry. So my knowledge is very much founded on practical observation.

The way I develop designs is very approachable and open to peers to review and contribute.

Here are my notes developing the drilling platform already seen (webpage)

Explaining in-advance - I've "inline'd" the calculations expressed in

Lisp - including the functions I have written. Being Lisp - that's

what's within the parentheses "(...)".

The answers are "machine-inserted" into the file on executing the

expressions.

So there is a persistent record of the logic, the calculations and the

answers in the one "design development notes" file.

So you could check-through my calculations I did four years ago for

the structure seen in that webpage...

--------------------------------- 190711_150x75x10_uneq-L_calcs.txt --------------------------------- (load-file "/Users/rds/Dropbox/files_ma/computing/programs_engineering/ma2nd_shapes.el") (load-file "/Users/rds/Dropbox/files_ma/computing/programs_engineering/ma2nd_parallelaxix.el") ;; Thursday 11 July 2019 21:41 ;; load-capacity of deck I am making for drilling off front of ;; barge... ;; find neutral axis ;; n=sum(M)/sum(A) ;; take base of section - in "L" presentation ;; stay in mm for now (/f (+ (* 65 10 5) (* 150 10 75)) (+ (* 65 10) (* 150 10))) ;; 53.83720930232558 ;; mm (! - not metres!) (let ((a1 (* 65 10))(y1 5)(a2 (* 150 10))(y2 75)) ;; (cons a1 a2)) (/f (+ (* a1 y1)(* a2 y2))(+ a1 a2))) ;; 53.83720930232558 (+ (ma2nd-rect-b-h-cx 10e-3 150e-3) ;; 2.8124999999999993e-06 ;; (* 10e-3 75e-3 (expt (- 150e-3 53.83720930232558e-3) 2)) ;; 6.935461736073553e-06 (ma2nd-a-y-parallelaxis (* 10e-3 150e-3)(- 75e-3 53.83720930232558e-3)) ;; 6.717955651703624e-07 (ma2nd-rect-b-h-cx 65e-3 10e-3) ;; 5.416666666666668e-09 (ma2nd-a-y-parallelaxis (* 65e-3 10e-3)(- 5e-3 53.83720930232558e-3)) ;; 1.5502974580854517e-06 ) ;; 5.04000968992248e-06 ;; m^4 ;; "Blue Book" => 501cm^4 => 501e-8 = 5.01e-06m^4 ;; so agrees. ;; sigma_max=My/I ;; M_max=sigma_yield I / y (/f (* 275e6 5.04000968992248e-06)(- 150e-3 53.83720930232558e-3)) ;; 14413.086960902861 ;; = 14.4kNm ;; point load at middle of deck = 2.44/2+0.450 (+ (/ 2.44 2) 0.45) ;; 1.67 (* (/f 14413.086960902861 1.67 9.81) 2 ;; there are two beams ) ;; 1759.5496421106243 ;; kg-f ;; if at end of deck (* (/f 14413.086960902861 (+ 2.44 0.45) 9.81) 2 ;; there are two beams ) ;; 1016.7639800431634 ;; 1 Tonne for even at tip (front) of deck ---------------------------- 190710_60x40x3_RHS_calcs.txt ---------------------------- (- (ma2nd-rect-b-h-cx 40e-3 60e-3) (ma2nd-rect-b-h-cx (* (- 40 3 3) 1e-3)(* (- 60 3 3) 1e-3)) ) ;; 2.7385199999999993e-07 ;; m^4 (* 2.7385199999999993e-07 (expt 100 4)) ;; 27.385199999999994 ;; cm^4 ;; agrees with "blue book" -------------------------------------------------------------- 230525 - getting Z, M_max not explained then - calculated here -------------------------------------------------------------- (* 355e6 (z-rhs-b-h-t 40e-3 60e-3 3e-3) ;; 9.128399999999997e-06 ;; m^3 ) ;; 3240.581999999999 ;; Nm ----------------------------------------------- 190710_loadcap_60x40RHS_2p44l_dblsup_190713.txt ----------------------------------------------- ;; M=WL/4 -> W=4M/L (/ (* 4 3240.581999999999) 2.44 9.81) ;; 541.5320599588908 ;; My first-principles calc for pure rectangular shapes gives this - ;; 542kg - for 60x40x3 S355

My main experience is "AutoCAD" in 3-D.

(from 3rd page of this PDF )

More recent is drawing the 3-D shapes going into the FEA models.

"Solidworks" is a respected program.

"AutoCAD" is an interpretter with most user-functionality scripted in

Lisp functions - which I am familiar with.

Yes definitely.

Immediately self-evident proof - I can work in factories, workshops and on construction sites, which are extremely teamwork interactive environments.

Example, although very text-heavy, is 3rd Bosphorus Bridge project, Turkey, 2015 , un-jamming this US$2.7Billion project which had stalled on weld issues.

You will be inferring yourself that "highly motivated" is a definite. I did get that bridge construction moving again, sorting the weld issues and working-in with skilled colleagues from other disciplines getting momentum.

It seems likely I will be one of those who always retains a motivated enthusiastic mentoring interactive character.

Yes already, to an extent.

Hand-pumped - to 700Bar - yes.

Machine - the 200Bar high-flow type - yes, some.

The already mentioned in FEA;

stiffened piston

:

I have done some maintenance and coaxing of hydraulic systems

I computer-program and know embedded devices must be imminent.

Update...

"embedded devices" - on 22Feb2024 I went to a Software Cornwall's

"Tech Jam" trying the "micro:bit" and saw / experienced how accessible

these are - which I programmed in "Python". Shown the "Arduino"

device and its programs in "C/C++". Pardoning technical-speak - I

have programmed in "C", designed around "malloc'ing" memory with

"pointers" data access and storage - so the "Arduino" is accessible to

me - noting its recognised power with analog inputs for machine

control.

"Seeing is understanding" - I had avoided embedded devices and

spreading effort, until this efficient introduction.

Including marine construction sites - yes.

I have worked in Trades of Welder and Steel Erector.

Marine - see Teignmouth Maritime Services 2018 to 2020. Marine civils

sites - mainly Plymouth Sound; also Brixham plus others.

Yes, though would be happy to start at zero and be mentored again.

I have done some programming of robots, so CNC machine-tool programming should be achievable.

This is a building area of knowledge with being a member of Carn Brea

Mining Society and volunteering at the Condurrow mine.

Yes I have used a

Holman rock-drill

. Drilling to 1.5m depth in a few minutes into very hard granite.

I broadly know of various rock-types, methods of

formation, etc.

Working in oil&gas, some matters I met were sampling the silt in

building the environmental case for offshore oil&gas developments.

I already hold Chartered Engineer status.

As mentioned already, I live very locally in Chacewater.

I can start "as soon as" - ie offer immediate availability.

(R. Smith, 21Feb2024, 23Feb2024 (embed.dev., more vis.previews), 25Feb2024 (eds.))