Here is my first ever pipeweld.

The text is a bit abbreviated, as time is getting late! Will make the description more complete later.

My pipe weld is:

This is the overall view of my pipe weld with my hand in view for scale. The bigger horizontal pipe is 115mm diameter and 6mm wall thickness while the side branch pipe is 75mm diameter and 5mm wall thickness.

Here is a close-up of my weld built up from the five weld runs of the procedure.

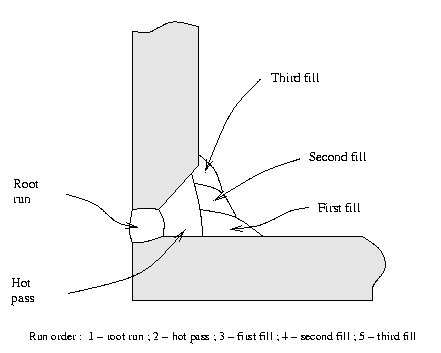

Here is a detailed diagram of the weld run sequence.

Responding to an earlier enquiry: yes, the "first fill" (3rd run) is asymmetric and unequal leg-length. It is about three times as wide as it is thick. I understood this to be the intention so focused heat into the hot-pass-to-lower-plate (2nd pass to larger tube) junction while widened the weld by sweeping the rod out to the side in shorter excursions. In doing this I was mindful of advice that any manipulation with a basic rod should be "s...l...o...w" in order to avoid the risk of slag inclusion. Likewise, focusing heat into the hot-pass-to-lower-plate junction aimed to get fusion plus melt out any lurking defects and slag.