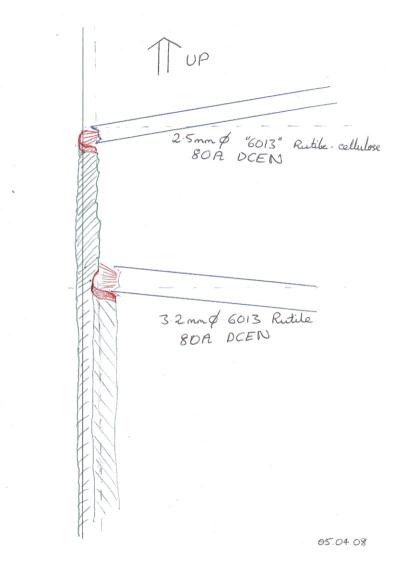

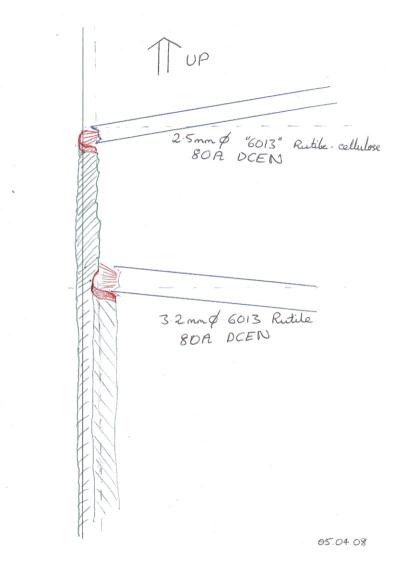

These are the conditions giving me sound vertical-up T-fillet welds with AWS E6013 welding rods run at 80A DCEN (direct-current electrode-negative).

6013 is the standard in the UK.

DCEN is the standard at the college I am attending.

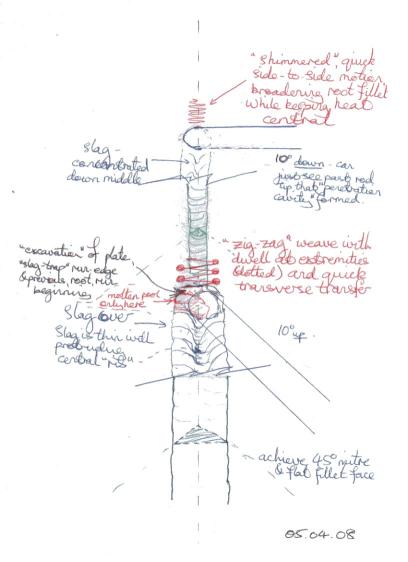

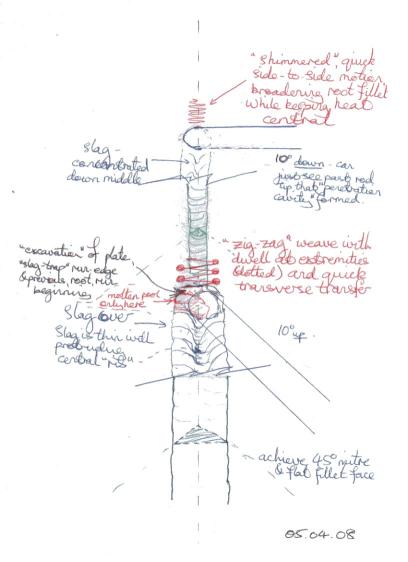

The reason for the drawings is because conventionally there should be

an up-angle on the root-run (fillet-corner run) rod manipulation.

However, I have yet been able to make upward-sloped-rod root-runs give

sound fillet-corner fusion. Whereas down-sloped root-runs, which run

against common concensus, give good fillet-corner fusion.

At time of writing, 05 April 2008 - if there is a price it is that the

root-run beads tend to be more humped and with sharper bead-to-plate

corners than up-sloped root-runs - which makes the capping run harder

to control smoothly.

[LATER NOTE (July08) - for the root run, convention is that the rod be horizontal or sloped slightly *upwards*. Later pages show I become in agreement with this.]

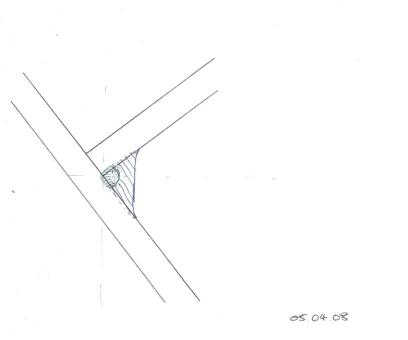

Side, front and plan (top) views:

The "artistic licence" (something not literal) in these pictures is that you do the root (fillet corner) run to completion, deslag and clean it - then do the capping run.

The major change for the capping run compared to previous vert-up T-fillets is that there is much less molten metal at one time. There is a very "dry" appearance to the weld area, with most of the metal even where there has been initial melting by the arc appearing black through the welding visor filter. This comes about by being able to sustain a stable run at lower current than before, by keeping the arc playing mainly above the melt line defining the top of the forming fillet.

Regarding the root run, I have not been able to achieve a similar change to an "arc ahead" control with a "dry" arc'ed-upon area with an up-sloped rod.

With a down-sloped rod there is natural deep cavity formation into the fillet corner, and the run speed is that which excavates while keeping ahead of the forming root fillet