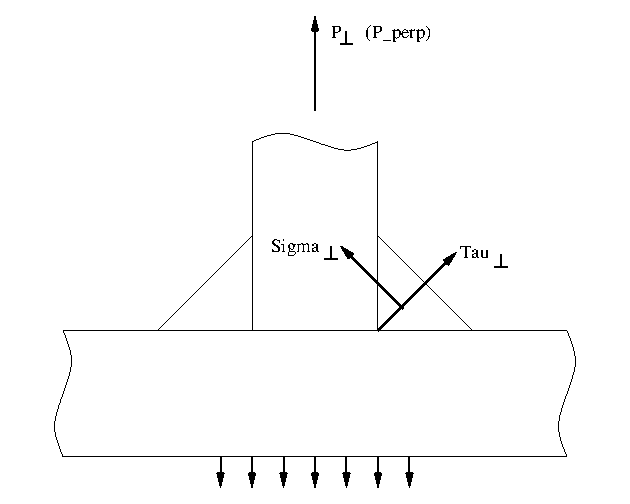

The nature - location, inclination - of fillet weld fractures seen in the Beam-Configuration Fillet-Weld Tensile Test - likely but not proven to be the same for other fillet welds in tension

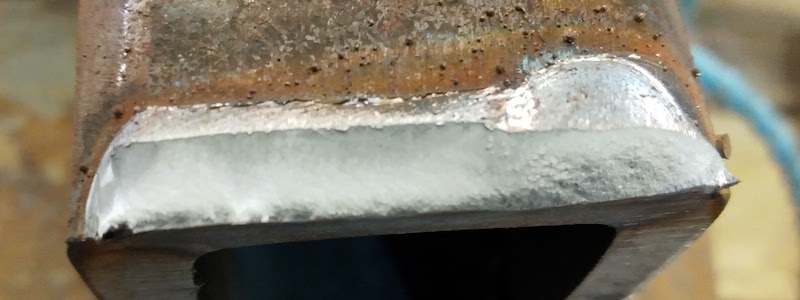

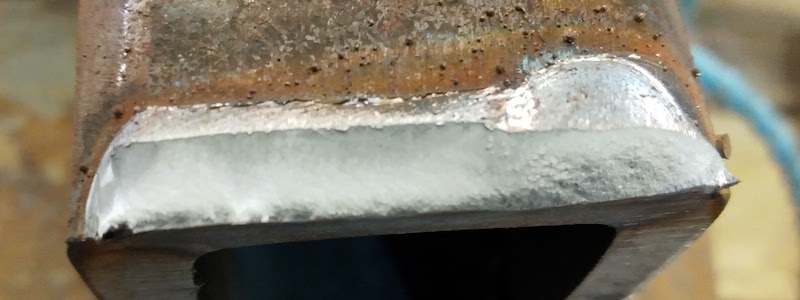

Example image of observed fracture shown here:

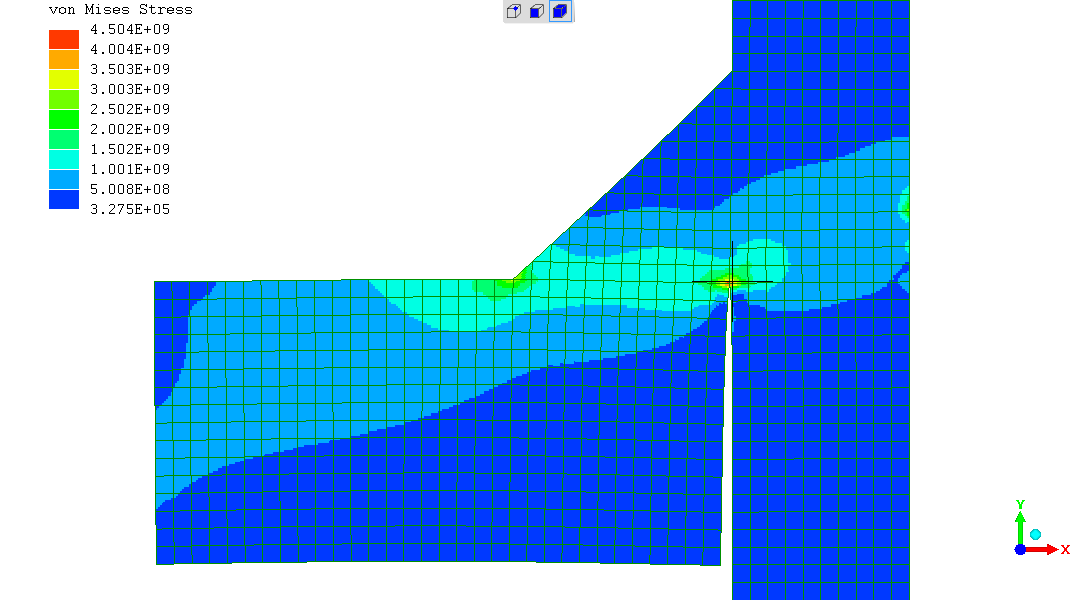

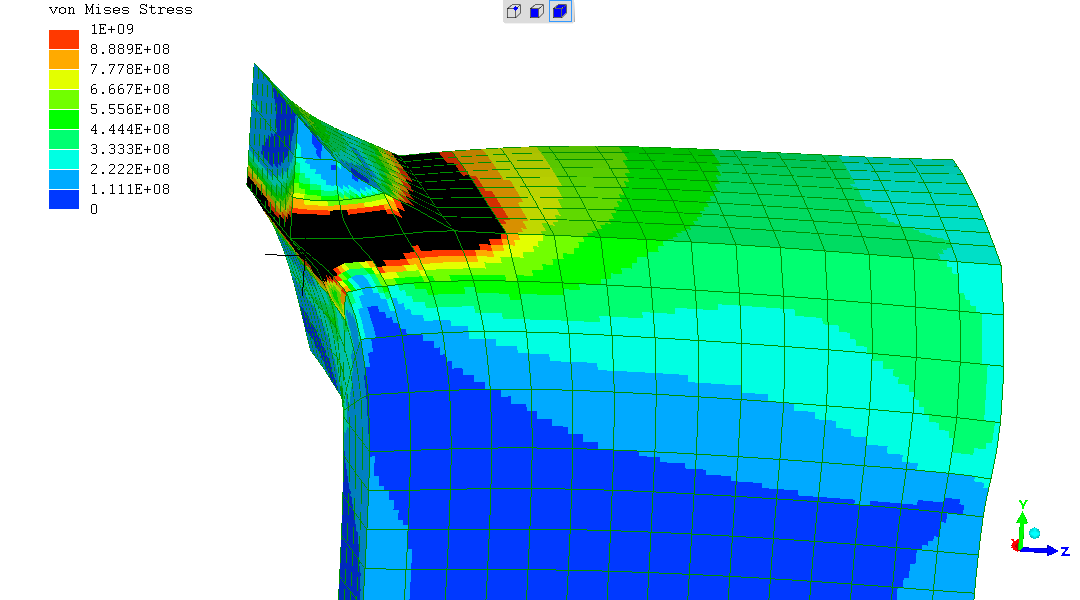

Both 2-D and 3-D modelling agree in predicting where fracture would be expected to occur and are correct.

2-D modelling has its prediction shown, arguably, in this one image on that page:

3-D modelling has a range of useful predictions. On fracture the best indication of where fracture will occur is in this image - the black region being at greater than 1GPa von Mises stress:

For both 2-D and 3-D...

The very close similarity between the observed fracture and the FEA-modelled "von Mises" highest deviatoric stress of expected (?) fracture seems remarkable and unmissable.

A familiar model supposes fillet weld failure in overload will be through the "throat" - the shortest thickness from fillet corner ("root") to fillet face. Which is on the 45degree angle to both "continuing" and "terminating" plate for a right-angled (90degree) fillet weld.

That is not seen for the BCFWTT samples.

Which shear (?) almost parallel to the fillet leg.

Discussion offered in section

"More detailed interpretation of fillet-weld tensile break measurements"

of "Fillet-weld test evaluation".

One image in that section:

Credit is given to Hicks for presenting the model.

I would say, were you interested in my opinion:

in a uniaxial tensile test sample the "necking" and final failure

occur along the 45degree angles, so guessing for a fillet weld that

anything which happens is along the 45degrees angles is very

understandable. In the absence of actual information. It was

difficult to tensile test fillet welds, as the forces needed to break

even a modest sized sample are enormous - many times the "power" of a

common "tensile testing machine". Hence the "in the absence of

observed information" caveat being "granted".

However - that "guess" was wrong as we have seen in my tests.

The Beam-Configuration Fillet-Weld Tensile Test readily tensions fillet welds to destruction - and we see what we see.

(R. Smith, 04Aug2024 to 05Aug2024, 11Aug2024 (compilation), 23Aug2024 (ed, black3d))