10mm diameter polypropylene 3-strand rope (today's general-purpose rope)

This is only about using ropes as I meet them in my work in steel fabrication and steel-erecting.

This means the cheap "general purpose" rope you buy in big coils from builders' merchants in 10mm and 12mm diameters. In rope terminology this is "polypropylene 3-strand laid rope".

10mm

diameter polypropylene 3-strand rope (today's general-purpose

rope)

coiled

5m length of 10mm rope

By the way - you want to practice tying rope of 25mm diameter if and when you can - as you meet 25mm rope with rope-hoists provided on the scaffoldings of construction sites.

Here is my list. If you are new to ropes and knots, come back to this later and don't fret now. The ones with names in bold - these are the ones I use really often. The others - I keep them "in practice" because they do something my commonly-used knots don't, which you must be able to do occasionally, sometimes in emergencies. A "timber hitch" is reckoned to be a commonly used knot, but I've never used it.

Stopper knots:

"Parcel-tying":

Loop forming

"Tying-off" - anchoring a rope to something:

"Tightening around something" hitches. Only to be used around fairly simple shapes - tubes and square-sections - when used to anchor a rope.

Joining ropes end-to-end:

"Rope-shortening":

This page is more about using rope than knots in themselves.

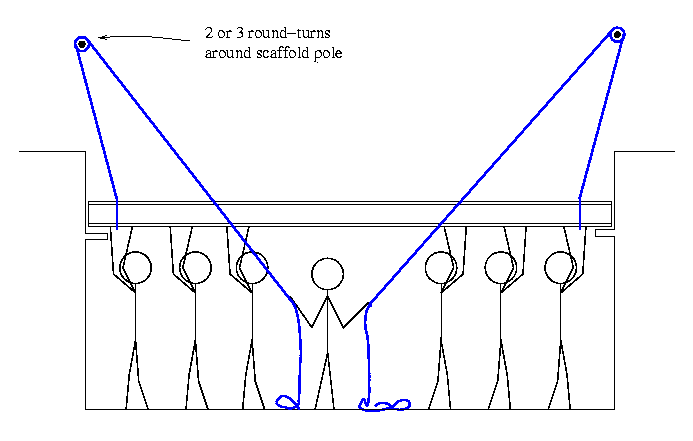

An important use of ropes are round turns. Round turns are used on construction sites to control loads much greater than a human could restrain unaided.

A round turn is when you wrap a rope around something so that you come back again on where you started the wrap, then go on another part turn to set off parallel to the incoming rope, back against the way the rope come in. Two round turns would be when you continue wrapping so the rope comes for the second time back to the starting point then another part-turn so the exiting "working end" is now running parallel to but against the direction of the incoming "standing part" of the rope.

A scene like portrayed will be familiar on construction sites

Here, several people are manually lifting a steel beam into place.

The ropes are there to hold the beam at its last position if the team

lifting have to let go. The person with the ropes keeps them drawn in

without slack between themselves and the beam. The rope slides around

the support - the scaffold pole in this case - under a light steady

tension from the rope person. However - if say the people lifting the

beam were to stumble, the weight of the beam would land on the ropes

between beam and scaffolding tube. The high load tension would

tighten-up the round turns and lock everything in place with friction.

As long as the rope person keeps as much as a featherweight of tension

on the outboard side of the round turns, the load is not going

anywhere.

A variation on this scheme is needing to position a load so heavy that it cannot be manually lifted, but were you are on a site with a crane. In this case you could get the crane to lower the load above where it is needed, rope it and transfer the weight to the control of round turns. Then by "jiggling" tiny lengths of rope feeding into the outboard side of the round turns, you can as slowly and steadily as you like set the load down on its final resting place.

And yes, you'd be correct in remembering - we've already mentioned a standard knot called a "round turn and two half-hitches". You lock the free "working end" side of the round turn with a couple of half-hitches around the incoming "standing part" of the rope carrying the load. You can do as many round turns and as many half-hitches as you like, in reality, so long as you end up with a well-formed knot.

If you know how to use rope, you will use rope very frequently - likely several times a day. And folk you work with will think you are absolutely a wizard if they haven't learned knots themselves. If they do know knots, they'll work with you and share their techniques. So you win both ways...

Keep your knots skills practiced, as you often need rope and knots in various "emergencies". For instance someone else might need immediate help because they are struggling and by being able to tie-off what you are working on so you can safely leave it, you can be there for your workmate(s).

There's only about twelve knots which cover every normal need of a steel construction worker. No need to learn a knot only used for fishing-line monofilament! So even though over a thousand unique knots have been classified, things can be kept simple.

To me the surprise as I set to "learning about knots" is that the standard general-purpose rope knots are not really "complicated" or "fancy". In fact, they all have a certain simplicity. And that is the thing - there is a beauty in simplicity.

Perhaps the difficult thing is that you are learning a new kind of "language". Some is formalised and you can simply learn it from labelled illustrations - "the standing part of the rope", "the working end", "a crossing-turn", "a bight", "a loop" and so on. More difficult are the "recognitions" you build up, about similar ways you twist ropes around in space. This is developing new skills of the mind which don't have any good way of describing them in words. But you can start by "learning by numbers", following very set always-the-same steps in tying a knot. As knot-tying generalities start to dawn on you, you get much more fluid, easily tying the knot you want with just a blur of your hands however the rope comes at you. You also see which knots have a lot of similarities (for instance a clove hitch and a constrictor knot are very similar). Again - don't freak - how-to-tie-knots guides will give you a good do-it-in-steps method, at which stage some people will already consider you an expert.

One surprise to a new learner is that a branch of knot-tying skills are the different methods known for tying one particular knot. Some would be learned by a specialist. Famously, as an example, a person who rides the winch line of a rescue helicopter will be able to tie a bowline with one hand, so they can tie to a person being rescued without letting go of their winch-rope. But as for the situation with the multiplicity of knots - a few faithful ways will see you through all your needs.

This is it:

Two different authors, Des Pawson and Geoffrey Budworth, have written books which have taken care of my rope-knot learning and guidance needs.

When you are new to knots, you sometimes "can't get started", but when you are memory-jogged about how to get started, it all flows just fine. So here is my tip - which makes sense in the time-period of writing (2008).

"Bluetooth" a picture of how to tie a knot you use often to your mobile phone. I take it you are looking at webpages showing how to tie each knot, so you can upload the picture which works for you to your phone. Then you can look at it on the phone's screen. You can zoom-in (it is difficult to see what's what on the tiny about 30mm by 25mm screen otherwise). So there you are, two months later, by your van, with only rope (no ratchet-straps with you today!) - and a half-a-tonne fire-escape to transport on the roof-rack. And after a quick flick through your mobile phone's options - you are the one who climbs up there and does the magic.

If you get into knots and ropes and work in the the steel construction business, you will soon be making yourself a "tagline". Well, that is what one of these is called in North America, apparently.

Here is a tagline

It's a length of rope about 2 arm-spans (about 3.5m) long, forming a lasso.

You can stow your tagline like this...

To carry it with you, tucked-over like this it will cram into a

boiler-suit pocket. Which is a good place for it when doing tasks

like unloading steel deliveries

Here's a detail picture showing the knots in a tagline. One end of

the rope has a stopper knot (a stevedore knot). This

won't easily pass through the loop formed in the other end of the rope

(a bowline).

Here is how a tagline is drawn in to a modest sized lasso loop when

you are about to use it for a "tightening-around" task

This is an example of how you would lasso a load

This is the sort of thing where your "rope skills" will first get really noticed. Our foreman cheerfully called out from the lift-truck "Were you a cowboy in a previously life?" as I controlled a badly "scissoring" load in the chains by pulling left-and-right on the end of a lasso-rope as he drove slowly. "Scissoring" is where a bundle load lifted by chains separates into two groups which rotate in opposite tilts in the chains (hence the scissor appearance). Both halves being tilted, either "half" could start sliding through the chains, when both would "let go" and javelin the floor in two directions. Not what you want to be near!

This makes the point about carrying your tagline with you! On this occasion, as the load rose off the steel delivery lorry and started to scissor with everyone backing away, I pulled my tagline out of my pocket, formed the lasso-loop and threw it from a distance over one end of the load. Yanking the lasso tight, I called the foreman to drive slowly and guided the load to where it needed to be, which was the first place the load could easily be landed on the floor. These are quiet slightly tense moments, by the way, when everyone knows there is a situation. If the load lets go, the length of rope keeps you clear of the first danger but you need to run well clear in case things start tumbling...

For a more secure grip, such as when pulling endways apparently as

to slip the lasso loop off what is wrapped around, a double-twist,

obtained by twisting the lasso into a figure-of-8 and folding it over

on itself at the middle, does the trick.

I routinely use a double lasso-loop when controlling chain lifts of stacks of SHS structurals (SHS = "Structural Hollow Square" - square tube). When the stack is still on the ground, I double-lasso the end of the stack and draw out the slack, then call the lift-truck driver to proceed. When lifted in chains, SHS structurals with end-plates misbehave, bundling-up tightly in a combined "twist-and-splay" which closes-up the square tubes in the middle, while splaying out at the ends in a mess of end-plates against tubes. Which is not stable - and elastic bending centrewards of the SHS's in the chains' grip stores elastic energy to make "spontaneous re-arrangements" rapid and wild. The double-lasso exerts a stabilising restrain preventing the structurals moving again beyond this first bundling (two turns of 10mm polypropylene rope gives over 2 tonnes of breaking strength - to back up the friction grip the double-lasso exerts). So you will be guiding your apparently stable SHS lift with your rope both to keep hands safely clear and to cause that all-looks-well stability.

Alternatively, you might need your tagline rope as a simple length of rope, in which case you push the stopper knot through the loop, giving you a convenient piece of general purpose rope. Did you note earlier I said "won't *easily* pass through a loop formed in the other end of the rope". You make the bowline (the knot forming the loop) so that the stopper knot, the stevedore knot, will just pass through the loop with a little effort if you need to make that happen...

Here is a sequence showing freeing of the lasso-loop

A bowline is the standard way of forming a loop from a piece of rope.

Here is "my" bowline

This shows the knot after forming the knot but before tightening

it, when it is carefully styled to help it form the model knot shape

(a properly styled knot is stronger than a haphazardly formed one)

A stevedore knot is a good solid large stopper knot which is also fairly readily undone.

A constrictor knot is very useful in steelwork, as the smooth surface of steel needs the grip of a constrictor knot. Yet the knot can be slipped off sideways over the end of a beam or tube when the job is done (in other situations outside steelwork, a constrictor knot is reputed to grip so tightly that it can only be removed by cutting the rope).

A constrictor knot has lots of uses when working with steel. Further on, I've shown a couple.

How you should tie a constrictor knot is best left to specialist

knot-tying websites. However, I am rather pleased with this method to

tie a constrictor knot, which I discovered myself when practicing my

knots when on a long train journey.

UPDATE on 03 February 2008 - find this method of

tying a constrictor knot is known and is the "standard" method shown

at the

"AnimatedKnots" Constrictor knot page

It's very quick and can be done in the mid-section of a length of rope, without needing use of the ends of the rope. Here's a couple of clips of movie of the method

Following is the sort of application of rope which makes it satisfying to have rope and knot-tying skills. At half-past-five one morning, I had two minutes to leave the house to get to my train. And needed to take this 9kg tin of welding electrodes to work with me ("6010" cellulosic electrodes 3.2mm diameter). It's too heavy for any bag. This solution came to me in an instant and I'd got it hanging from my shoulder by its rope "carrying strap" as I strode out to travel through busy central London by train including the interchange stations.

Here is another application of a constrictor knot which illustrates

everything about what rope-using ability is about.

[want good pic. of using a "lifting bar" - constrr_bar_76s.jpg]

To move a very heavy load around on the floor, you can loop the object - often a beam or heavy flat - with the rope and knot the rope to a tube at waist level, so that by just kinking your legs then straightening them, you can hover the load off the floor and shuffle it where it needs to go. This looks very competent. You can form up a rope loop with two handles for two people to share the lift... And so on. The rope skills are adaptable general problem-solving methods in the "kit" of a steel construction worker.

R Smith, 02 February 2008