Abbreviations used

In April 2015 I formed a favourable opinion of DQE colleagues Nuvit Sahinturk, Melike Ozbekoglu and Erhan Turgut as they answered questions on ultrasonic testing in a project meeting of the 3rd Bosphorus Bridge project.

I therefore spoke with them after this meeting about a concept I had formed regarding Radiographic Testing (radiography), and what follows is the outcome.

DQE, otherwise known as "Dizayn", provide a range of Non-Destructive

Examination (Non-Destructive Testing) and engineering services, is

based in Kartal in Istanbul, Turkey, and operates in several

countries.

Their website is

http://www.dqe.com.tr

A separate page provides a general comparison between RT and UT, plus some comments specific to the application of NDE to the 3rd Bosphorus Bridge / Yavuz Sultan Selim Bridge.

A quote (price) has already been offered for the RT solution as described following.

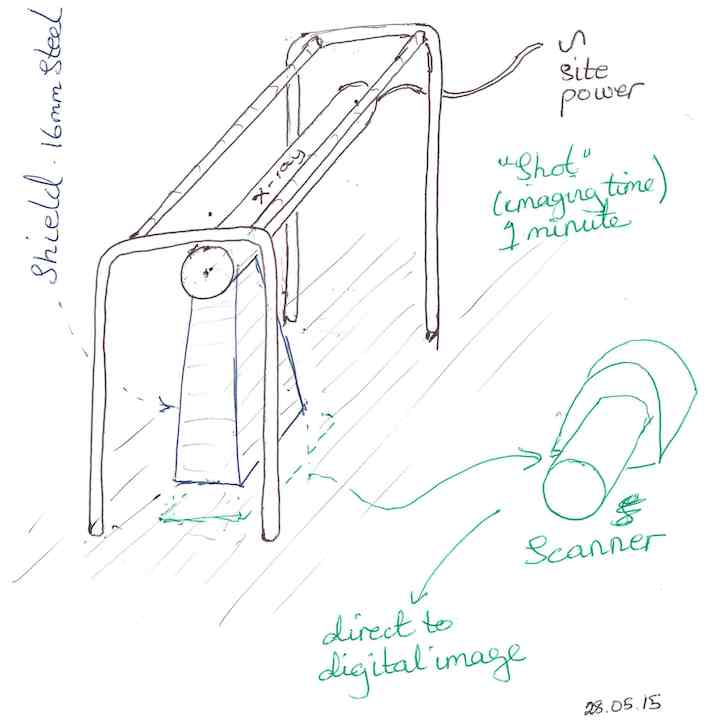

To meet the needs of the Project, it is clear that an RT method applied the the bridge deck assembly activity needs to have these characteristics:

The following excellent solution, which meets all requirements elegantly, is made possible because the RT needed, for the highly-stressed deck-plate seam welds making coplanar butt joints between flat plates of equal thickness, is the simplest case of RT.

Practicality of the solution is vastly assisted because the large moderately heavy equipment will rest on the flat or slightly-sloping steel deck plates held-down by Gravity.

Given the 14mm and 16mm thickness of the deck-plates and therefore the thickness of the seam-welds butting them together; citing the specific example of 14mm deck plate thickness, the following solution fulfils requirements:

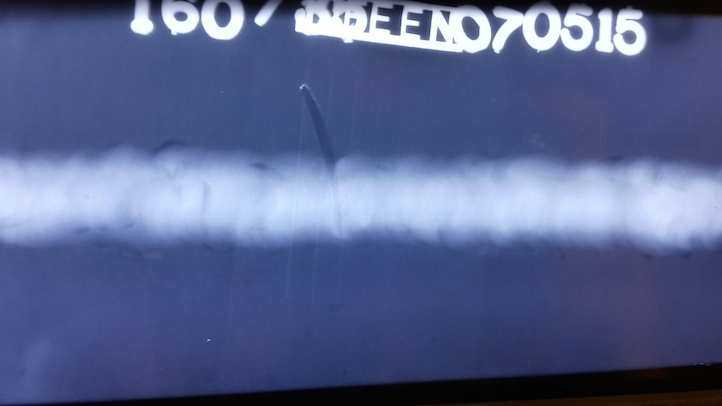

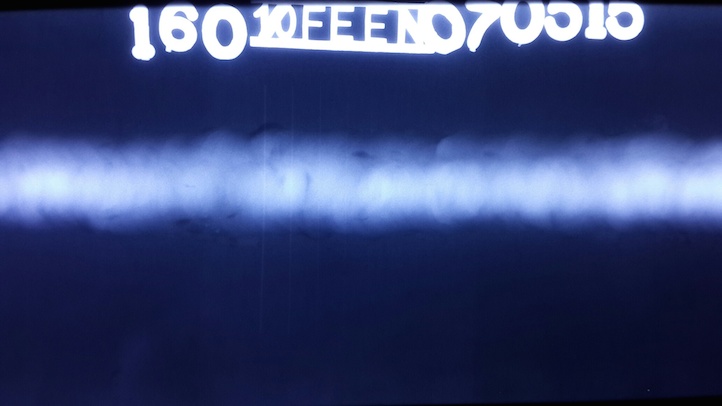

The radiographs produced by this radiographic solution are shown alongside a radiograph using Ir192 Gamma source. All images are of the same weld sample, in the same location (unfortunately, the IQI does not remain in identically the same position).

It must be explained;

the imaging "optics" are identical to the offered solution - same

source, same geometry of "shot".

However; because of the expense of obtaining the scanning equipment,

which the NDE Contractor does possess and use in another country, the

imaging was done using conventional "wet film" radiography.

Furthermore, the images are not properly scanned from the radiographic

film but are obtained by photographing the radiograph as seen on a

viewer a human uses to view and radiographically interpret the

radiographs.

This is declared for appropriate disclosure; however it is believed

that the image qualities are representative and the comparison of

image quality is valid.

160kV; 350mm s-o-d

160kV; 500mm s-o-d (this image has better density but little better resolution than the "shot" at 350mm s-o-d (see IQI resolution))

Representative best obtainable Ir192 "shot" (radiograph quality is

limited by low image contrast)

The X-ray radiographs are vastly superior.

Indicatively: 3 IQI wires can be seen in the Ir192 radiograph, whereas

5 IQI wires can be seen in both X-ray radiographs.

The quantitative 2-IQI-wires improvement in radiograph resolution

accords with the qualititative impression of the X-ray solution giving

a much higher radiographic quality than the Ir192 technique.

The quote and proposed contract is for as many images in a day as the team on-site can reasonably take; for a fixed Contract duration of several months.

Noting 1 minute per shot, this amounts to a lot of radiographs and the seams can be quite extensively radiographed.

The structure of the Contract offered is explained as follows. The

fixed cost of the equipment is high; however the variable cost per

"shot" is low, given the re-usable imaging plates.

Therefore: the NDE Contractor requires a guaranteed minimum Contract

remuneration to cover the capital costs of the equipment committed to

the contract. However, awarded this Contract, the Contractor is then

happy to apply the equipment to take as many radiographs as the

Customer wants.

(R. Smith, 02Jun2015 22Jun2015, 12Apr2017)