Updated mill: Rod-mill with new end-cover working well [video on my YouTube channel].

Mill now outwardly presents planar end-cover; secured by six threaded

studs through six anchors on the outer shell of the mill against which

nuts draw-up the cover.

The end-face of the shell has been made as flat as possible using

manual grinding with a large angle-grinder.

Metal-to-metal contact of shell end-face to end-cover plate is close.

Batch test charge of 10mm granite chippings, dried for 1 hour at

110C.

Ground for 30 minutes with all rods in mill (as previously), so

maximum rod size is 40mm.

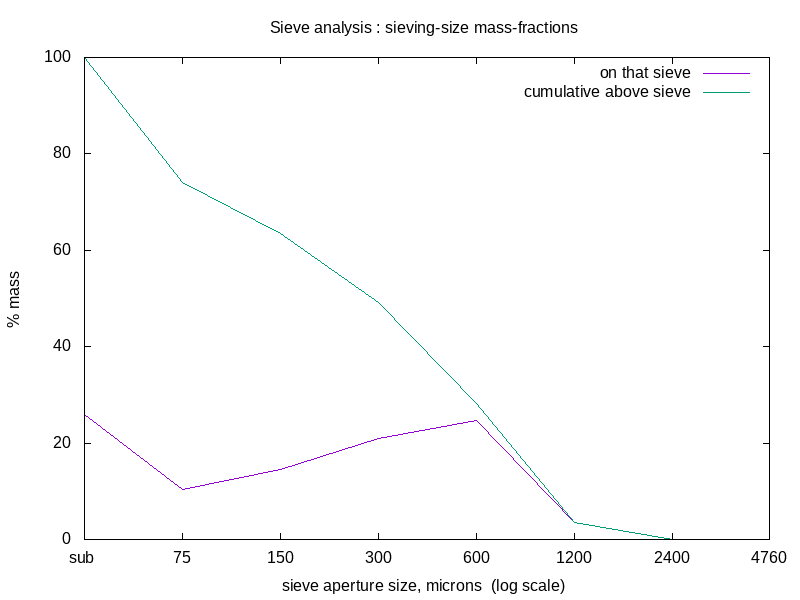

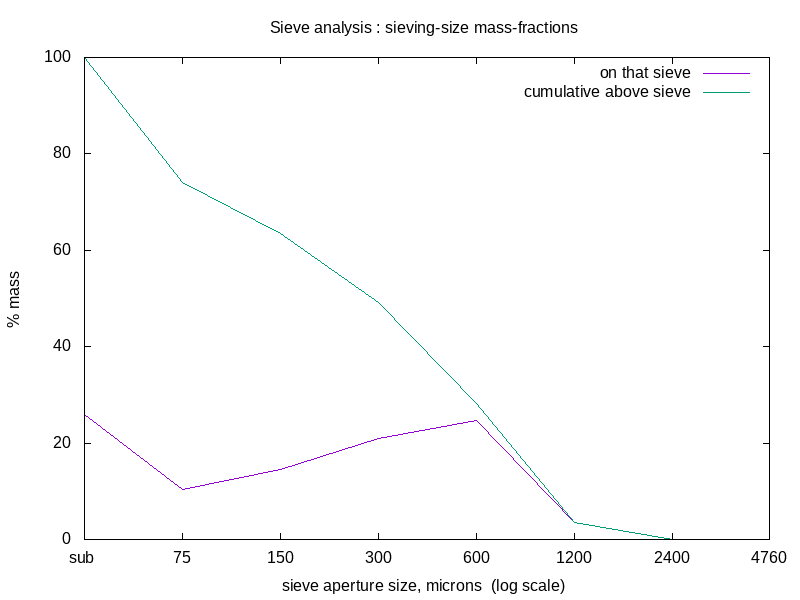

The masses on each sieve were:

Aperture(microns) mass(g) 4760 0.5 2400 2 1200 136 600 960 300 820 150 564 75 406 -75 1016

The sum total of these masses is 3904.5 g (3.9045 kg)

Of the 23July2025 rod-mill comminution:

On this 23July2025 rod-mill comminution of 10mm granite chippings - a "test grind":

Expanding on the latter point:

the "lifters" on the inside of the shell are vastly oversized. The

comes from a misunderstanding. The "lifters" should be very few

millimetres dimensions in height and width. "just" to ensure that the

charge, of grinding medium / rods and charge / mineral cannot "skid"

within the shell.

The "lifters" have been roughly cut back to about 20mm tall - still way too tall. The largest rods are 40mm diameter and it seems probable they are carried high in the mill regardless of mill rotational speed.

The oversized "lifters" cause the mill to always "cataract"; never

"cascade"?

Should the mill work more in "cascading" mode than "cataracting" mode?

It is certainly correct that experience is accruing...

(R. Smith, 29Jul2025)