In reality - I need to make an "Arduino" do something like say "Hello,

World!".

Maybe measure the voltage input from a thermocouple and from its

calibration curve report the temperature the thermocouple is at.

However : this is the sort of destination which would draw me...

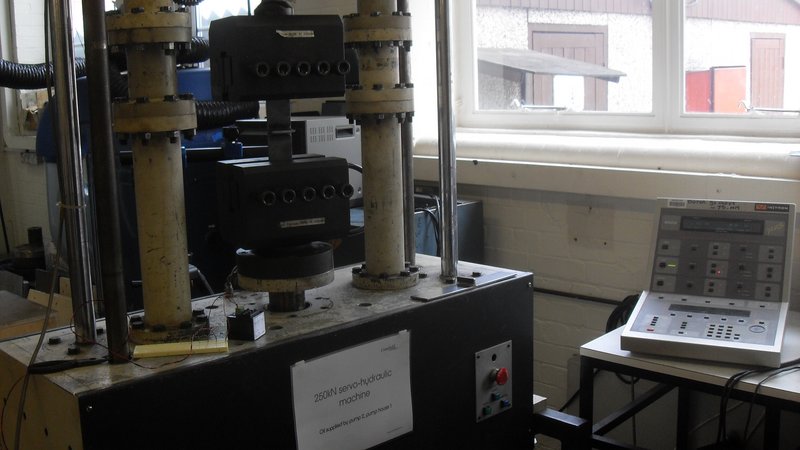

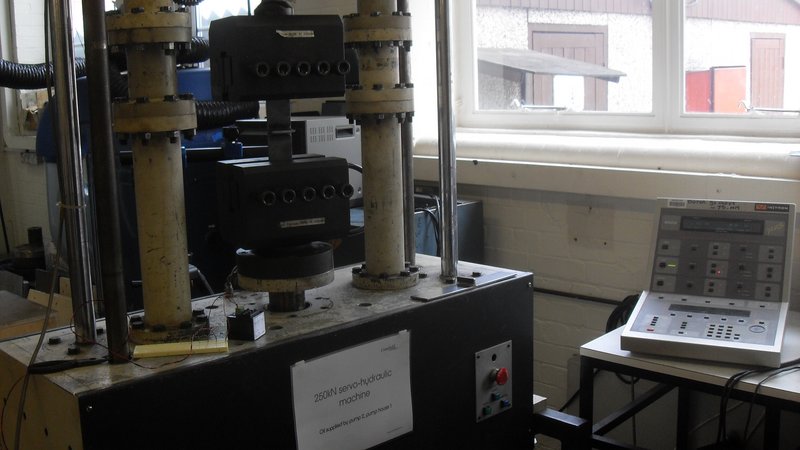

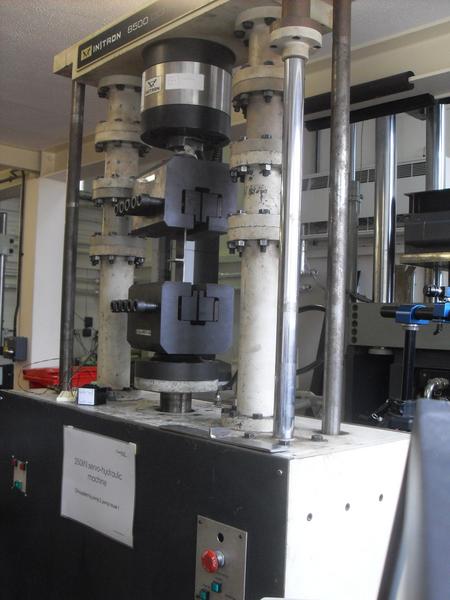

This is about harnessing something like an "Arduino" to control a test for Metal Fatigue [Wikipedia external link]

Just to clarify - the sample is the relatively tiny little thing

between the big jaws of the machine with that line of five clamp

bolts....

The sample is vastly smaller than the machine testing it.

The problem behind all seen here:

Looking for something which will do squillions of constant simple "sine-wave" load-cycles.

Here one is...

This is an early-stage fatigue-crack

The horizontal flaw is left by the welding and is considered

acceptable (and a pig just flew past the window)

The vertical part is the growing fatigue crack - propagating downwards

across the load-direction.

The fatigue crack has initiated in the stress-concentration at the

root of the "weld toe intrusion".

It would grow progressively until the remaining load-bearing section

is so diminished it snaps suddenly under the regular load.

Bridges we could do something about.

(ships no - have profusions of welds and unavoidable sharp edges - eg rectangular corners in holds and deck-to-panel joints - plus the independent issue seawater corrosion - both tending to 25year service-life)

How to do this - change the fatigue outcome?

Well as a welder it's bleedin' obvious. Get rid of those weld

toe-intrusions.

Do what's analysed by Finite Element Analysis modelling here:

FEA simulation of fillet-weld "toe" with specific weld features

Adjust the weld until they disappear and then chase-away any stick-in-the-muds who object to the new appearance of such welds.

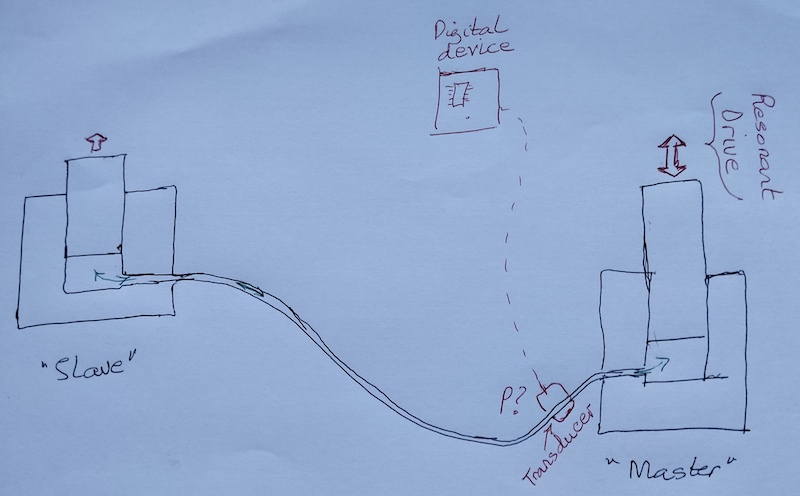

[on page my test-rig ]

There is no obvious upper limit to the size of this test.

Its notable characteristic : the testing equipment is much smaller than the sample being tested.

The "master" and "slave" cylinders could both be regular commercial hydraulic cylinders which can be bought "over-the-counter" at a hydraulics shop.

For the convenience of a standard mass-produced well-tested design

built to high specification for a competitive market.

Wise words from a hydraulics person - it's not cycles which kills

cylinders; it's inactivity. In other words : there is every

confidence that a cylinder intended to manually jack beams

straight etc could do tens of millions of oscillating cycles.

The concept is a resonant system.

It's

Simple Harmonic Motion

[Wikipedia link].

Energy is conserved - the energy cyclic transfers between kinetic and

potential energy. The sum of kinetic and potential energies remaining

constant.

Apart from friction and like losses - so you have to apply some

driving force.

Practical / pragmatic point : the "slave" cylinder, a tough piece of

equipment, doing the work where things go "bang" has nothing

additional attached to it. All the mechanism is removed from harm's

way.

A pressure transducer near the "master" cylinder is probably enough

control to start with. That too therefore being safely out of harm's

way.

Were a miraculous path to open-up - a load-cell between the piston of

the "slave" cylinder and the sample, datalogged through a fine cable,

would be the ideal. Another achievable.

These are where the microprocessor control comes-in.

"Top-up" the energy just the right amount to keep the oscillation

constant and invariant... Constant peak pressure / constant peak

force. The microprocessor must instruct some sort of drive which

keeps the oscillation going.

Getting the oscillation started would take a bit of logic. With a

stationary sample the "drive" would have to scan the frequency of

actuation until it finds the resonant frequency of the system - when

the sample starts to oscillate...

Then drive it up to the target oscillation peak.

Start recording the number of cycles and keep going until the sample

breaks (the pressure oscillation stops).

A great first-base would be to to make a spring hanging from a bracket bounce up and down...

(R. Smith, 26Feb2024)