Rule in pictures to give scale is blade of 300mm/12inch combination-square.

The winch barrel is 115mm diameter and 100mm wide. The reason for the limited width of the winch barrel is to help investigate the self-layering (of the rope) property winches are supposed to have within a range of winch to lead-block or fairlead distance. To give a "fleet angle" within the range 1/2degree to 1~1/2degree. According to what is written in books optimum is given by a "20:1 rule" for winch-to-fairlead distance. Giving 2m in this case - a manageable distance for an experimental set-up.

The limited width will also mean that layers are soon completed, so I should be able to see how the winch behaves with multiple layers of rope.

The intention is to make a couple of stands with simple bearings and put a hand-cranking handle on the winch axle. For a simple experimental / investigative device.

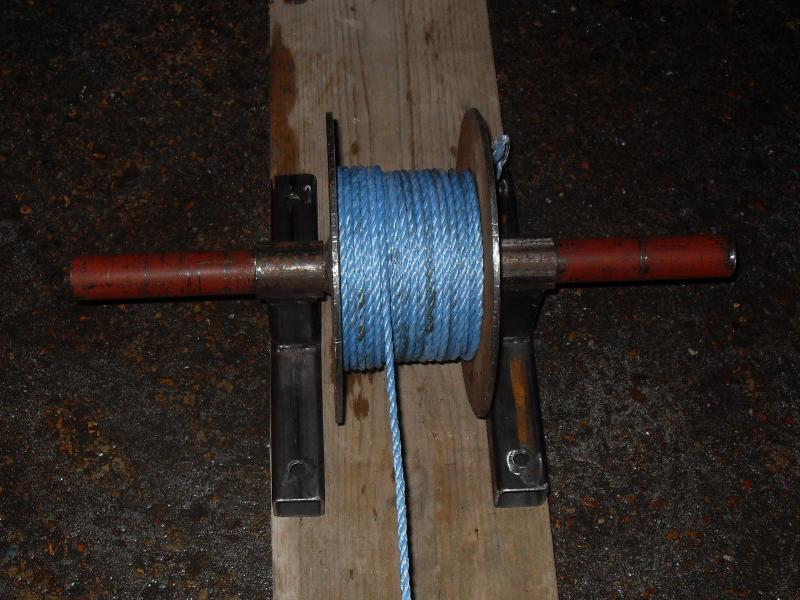

Two views of the winch-barrel on its bearings & stand.

The stand and bearing assembly isn't welded at all yet. Had a short good session getting from zero to ready to weld off, then quit while I was ahead.

Welded-off bearing-and-stand assembly. Started on handle.

Handle completed. Handle grip is sleeve freely rotating on structural shaft of handle. For simplicity, handle boss is lightly welded to axle with superficial welds - quick and easy to do and hopefully easily ground off to release handle.

Made fairlead and screwed winch and fairlead to scaffold plank with wood-screws. (removed handle from winch - attachment was low-current low-penetration Rutile welds for exactly this reason)

Rotated the winch by gripping the protruding axle ends. Dragged an offcut of metal attached to the far end of the rope across the ground to provide some rope tension.

Immediately see

In the second picture, showing close-up the winch-drum with wraps and layers of rope, there is an error in the wraps on the right-hand-side. A wrap has been missed and the rope is not tightly packed. Reason? Maybe the winch is not square to the direction to the fairlead (the left-hand-side wrapped fully packed then reversed direction perfectly).

Welded the handle back on - deliberately low penetration humped weld-bead at about 35A with 2.5mm dia 6013 - so when grind off weld bead, handle is freed.

Just wrapped the rope around fairlead and tensioned up the rope. Immediately problem becomes obvious. The rope as it comes onto the drum and for the first half-turn burrows through the wraps and under the layers of the neatly layered rope.

Got to set this up and try something like hauling a log across a field - see how it behaves on a full-scale test.

Now have question - do rope and multi-layer spooling on a winch drum go together???

(R Smith, 17.11.09, 18.11.09, 22.11.09, 23.11.09, 27.11.09, 04.12.09)