Project seeking fatigue-resistant T-joints in the 5mm to 6mm plate thickness range.

With the test conditions applied, a T-fillet weld made with MIG or FCW-MIG would endure about 250,000 cycles to break.

Test conditions are:

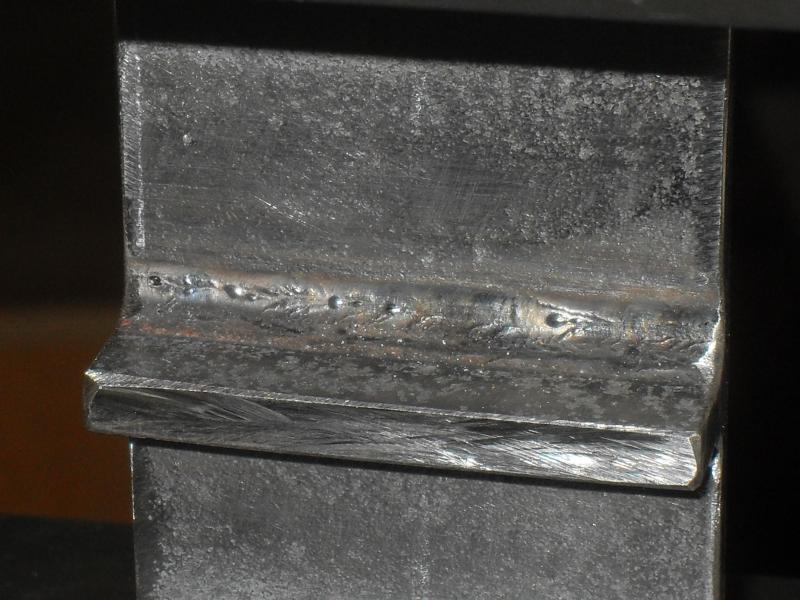

The following weld being tested might be commercially viable. By a series of sequential reasons a hybrid laser/MIG weld with the external bead shape TIG-dressed might perform well in fatigue.

First test getting under-way

I stopped the test at 1,680,305 cycles not broken (a mind-boggling high endurance!).

Same test conditions.

The sample - identical to in first test. Smooth rounded shape is natural outcome of TIG-dress.

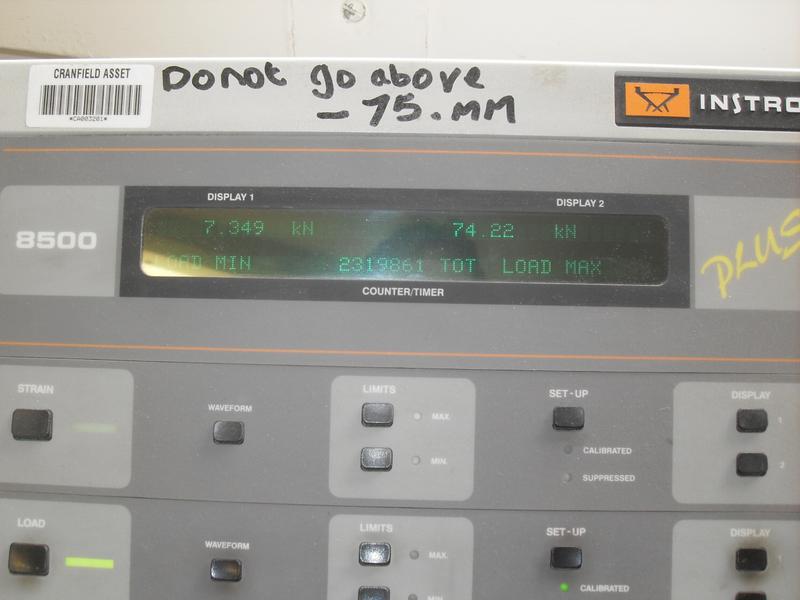

Test machine instrument-panel as seen 2~1/2days into test.

Halted this test at 2,320,006 cycles not broken.

These performances are beyond anything which could have been imagined. Standards indicate that perfect hot-rolled plate and sections fatigue at around these endurances at this high stress level!

In all honesty - literature said this was possible. However, having seen fatigue taking apart conventional welds, seeing is believing. The difference between the literature and here is that the tests in the literature are on welds which are not commercially viable. These welds might be.

R D Smith, 02 August 2011