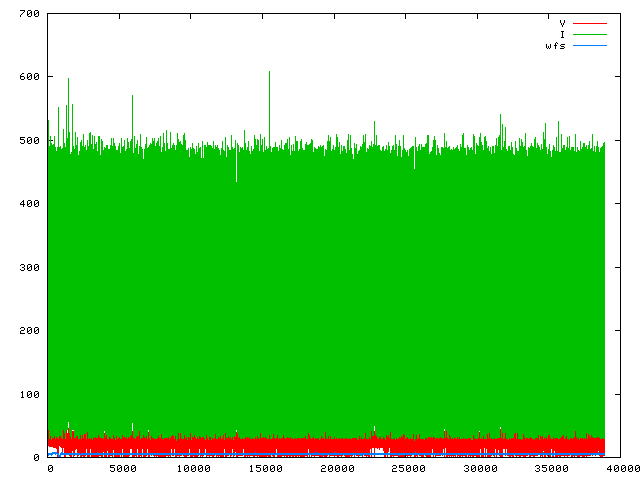

1105191535P01pulselo139A19p9V

1105191535P01pulselo139A19p9VThese welds were performed on 5mm steel plate with 1.2mm diameter steel MIG wire and Ar/20%CO2 shielding gas.

All traces are for Lincoln Electric's "RapidArc" - a variant of Pulse-GMAW claimed to give stable welding at fast run rates.

Sampling rate for all data-logging shown here is 20kHz.

I will not be re-writing these notes, but several comments are misguided.

It is clear that I have identified "pure pulse" as the "nice" condition. That's the "200/1.30" condition. "RapidArc" is gone, becoming "pulse transfer" as generally understood. The "420/1.20" condition has little of "RapidArc" left.

I know now that there is intended to be a "dipping" event, which can be seen where the voltage goes to a low value presumably representing the voltage drop of the Ohmic resistance of the wire bridging between contactor tip and weld pool. The "dipping" ("shorting") event happens at low current always. So as I do credit at the time, it results in no spatter. It is clear the brochure description of "RapidArc" is compatible with the waveform measured. The second small current peak does indeed look to be designed to depress the weld-pool away from the wire when the short-circuit breaks, as claimed in the brochure(s).

Trying welding again - doing a T-fillet weld on 6mm plate using 1.2mm wire, example conditions giving excellent results were

Bit of spitting; cold?

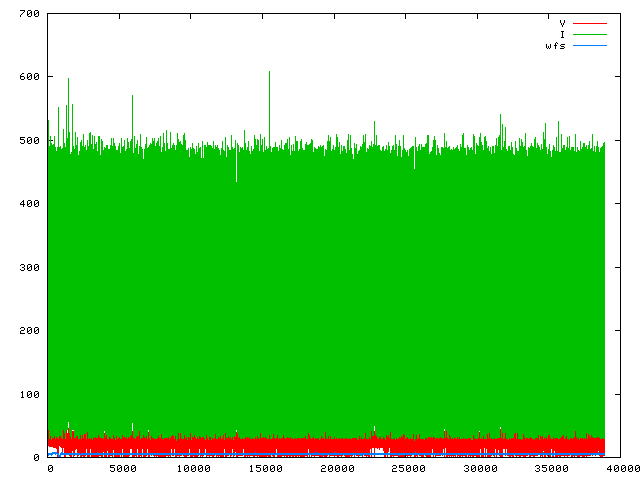

1105191535P01pulselo139A19p9V

1105191535P01pulselo139A19p9V

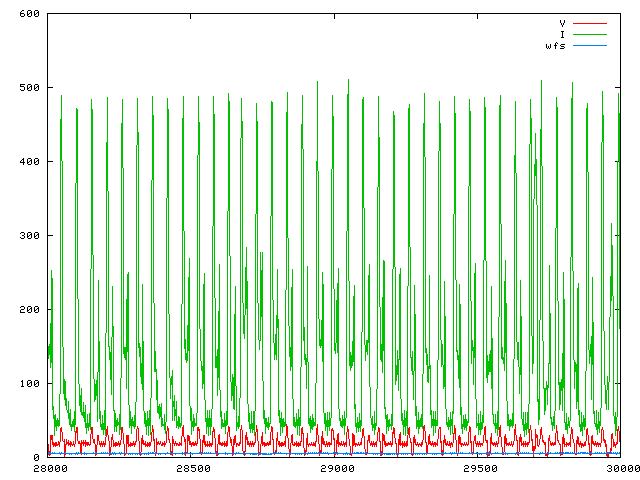

1105191535P01pulselo139A19p9V_28000_30000

1105191535P01pulselo139A19p9V_28000_30000

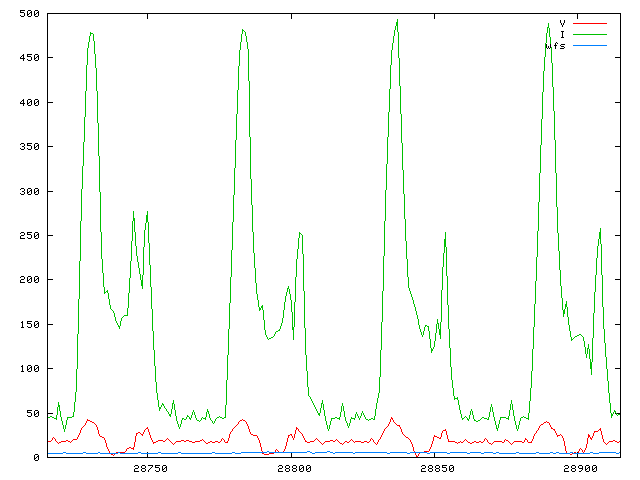

1105191535P01pulselo139A19p9V_28715_28915

1105191535P01pulselo139A19p9V_28715_28915

Fairly nice

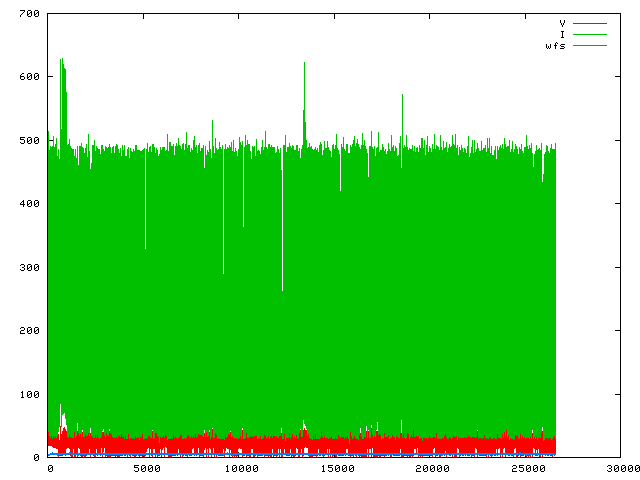

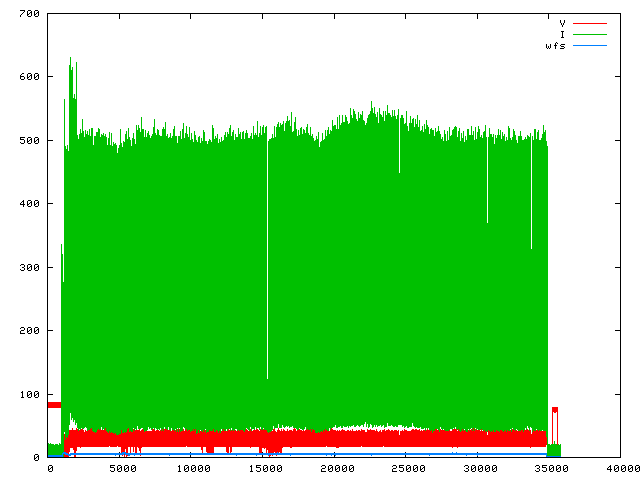

1105191535P02pulselo140A20p4V

1105191535P02pulselo140A20p4V

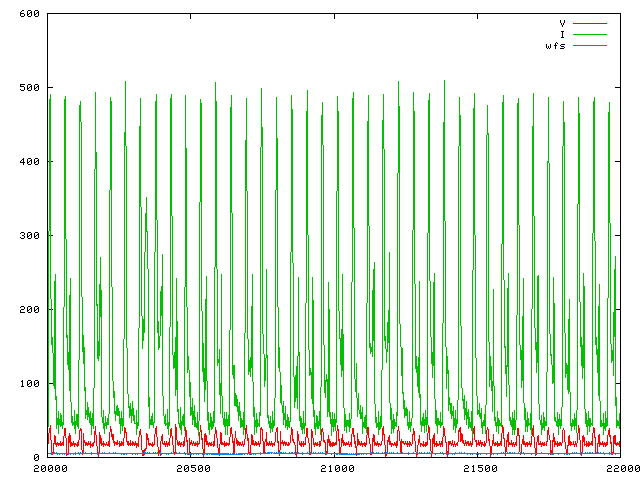

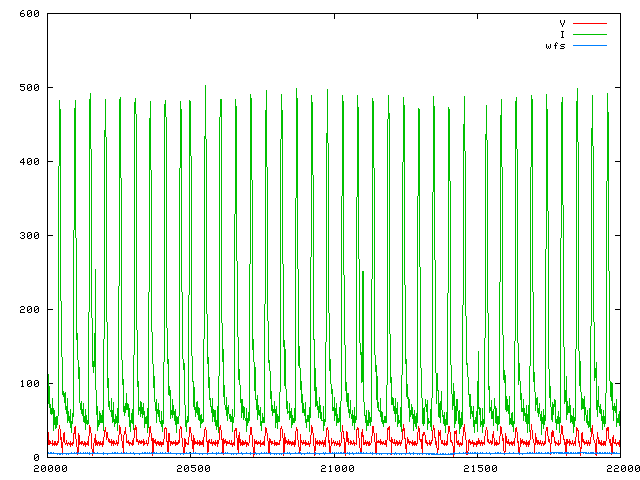

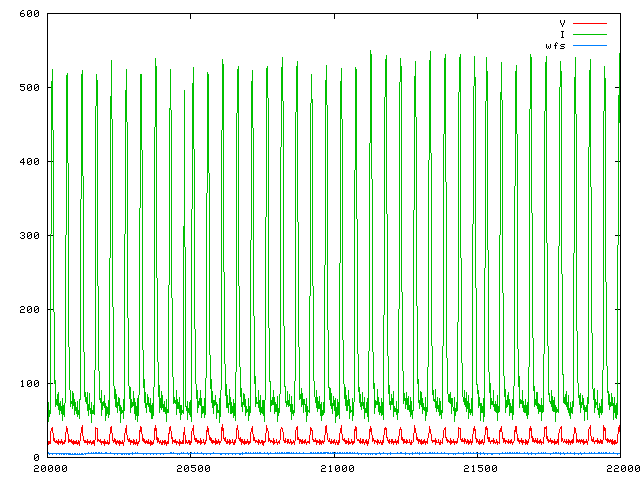

1105191535P02pulselo140A20p4V_20000_22000

1105191535P02pulselo140A20p4V_20000_22000

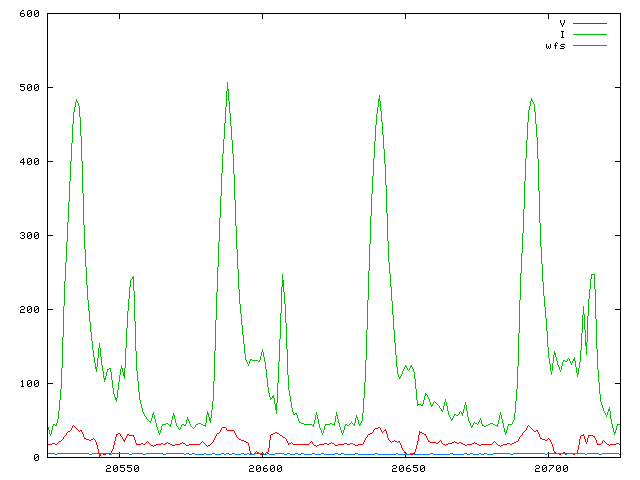

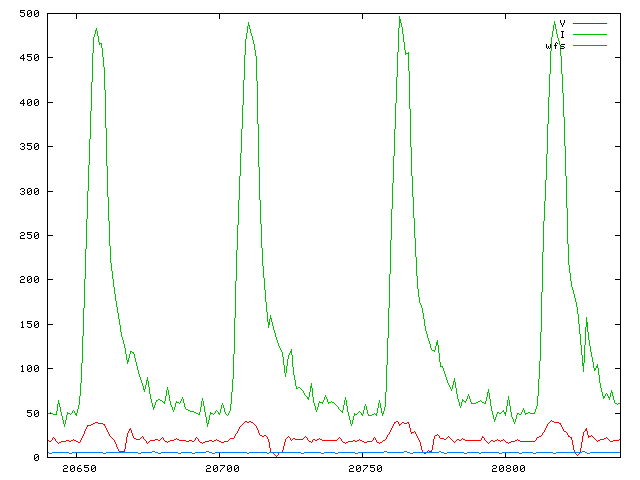

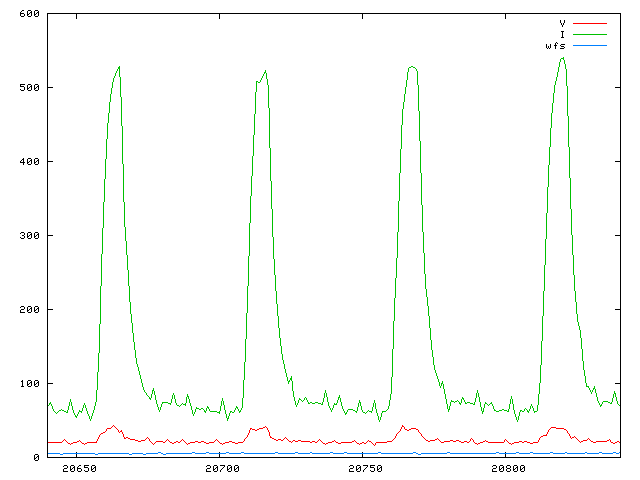

1105191535P02pulselo140A20p4V_20525_20725

1105191535P02pulselo140A20p4V_20525_20725

Good

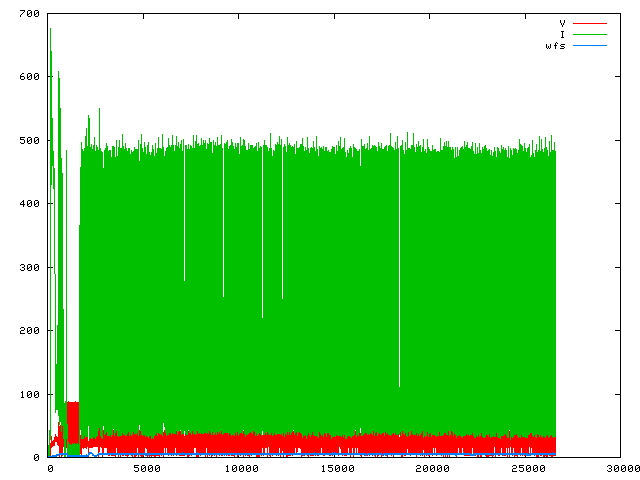

1105191535P03pulselo134A23p7V

1105191535P03pulselo134A23p7V

1105191535P03pulselo134A23p7V_20000_22000

1105191535P03pulselo134A23p7V_20000_22000

1105191535P03pulselo134A23p7V_20640_20840

1105191535P03pulselo134A23p7V_20640_20840

Good

117A 22.2V

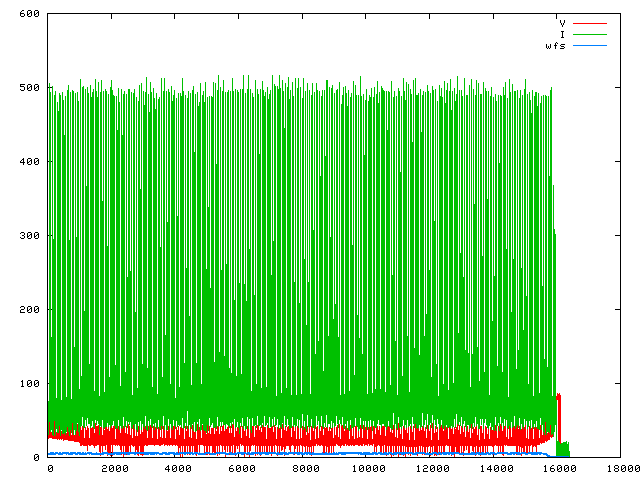

1105191535P04pulselo117A22p2V

1105191535P04pulselo117A22p2V

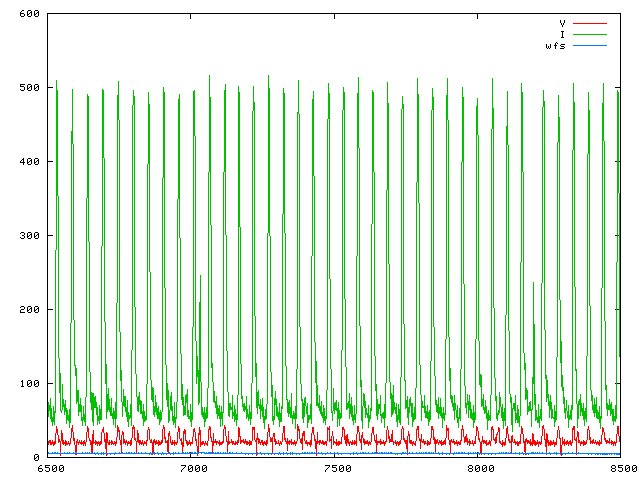

1105191535P04pulselo117A22p2V_6500_8500

1105191535P04pulselo117A22p2V_6500_8500

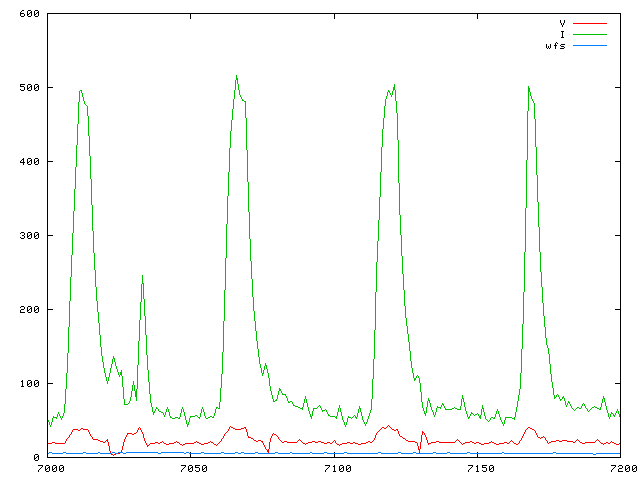

1105191535P04pulselo117A22p2V_7000_7200

1105191535P04pulselo117A22p2V_7000_7200

Good; warm (as in unnecessarily high heat input?)

1105191535P05pulselo136A26p1V

1105191535P05pulselo136A26p1V

1105191535P05pulselo136A26p1V_20000_22000

1105191535P05pulselo136A26p1V_20000_22000

1105191535P05pulselo136A26p1V_20640_20840

1105191535P05pulselo136A26p1V_20640_20840

Choking (bad shorting?); not good welding condition

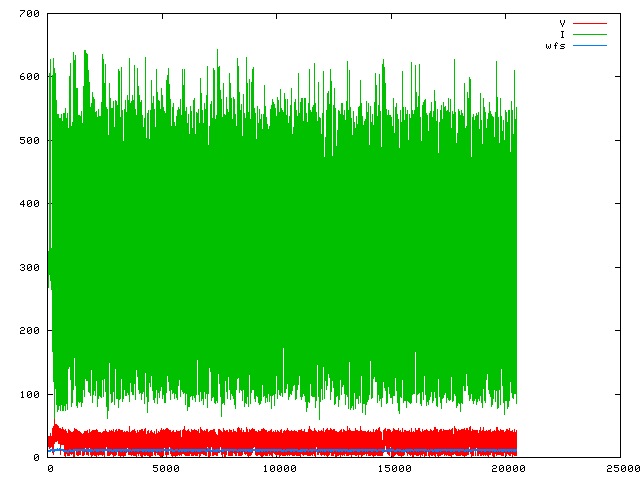

1105191340P09pulsehi247A23p2V

1105191340P09pulsehi247A23p2V

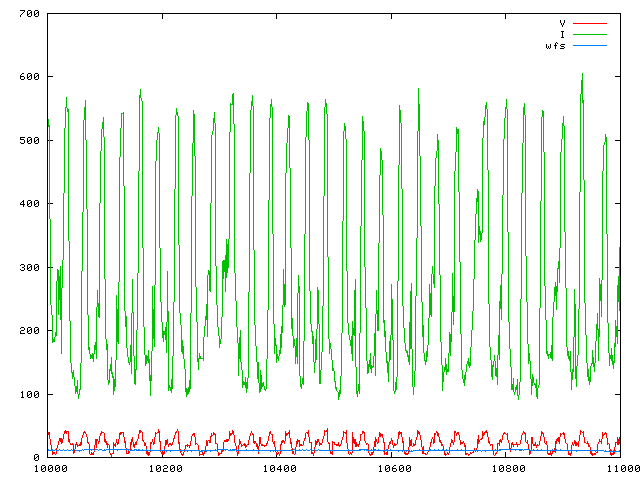

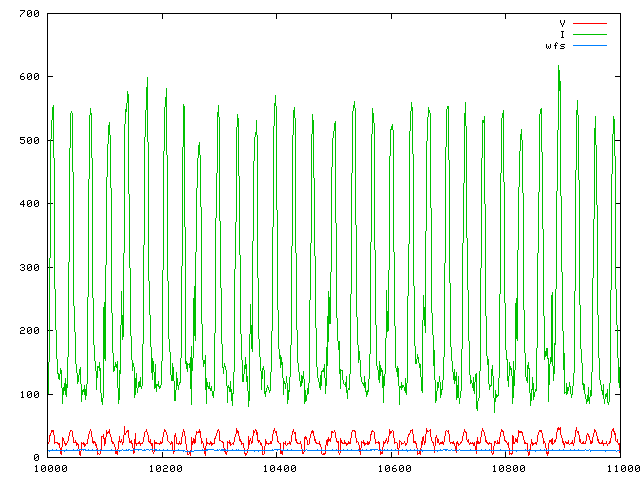

1105191340P09pulsehi247A23p2V_10000_11000

1105191340P09pulsehi247A23p2V_10000_11000

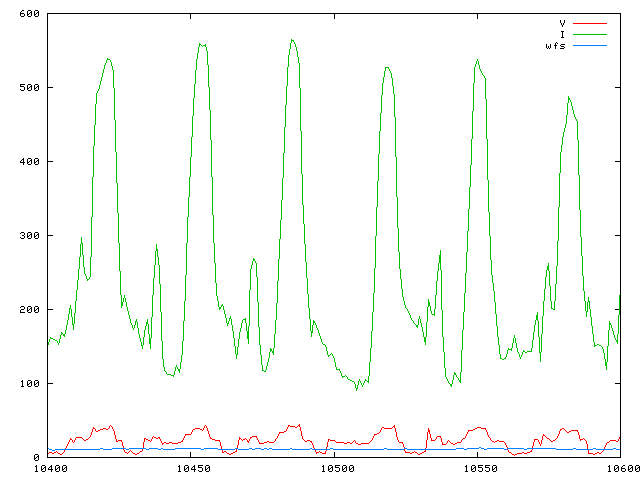

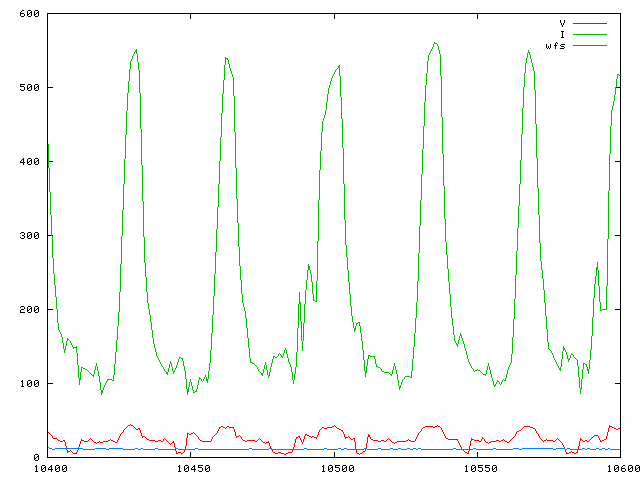

1105191340P09pulsehi247A23p2V_10400_10600

1105191340P09pulsehi247A23p2V_10400_10600

Spitting

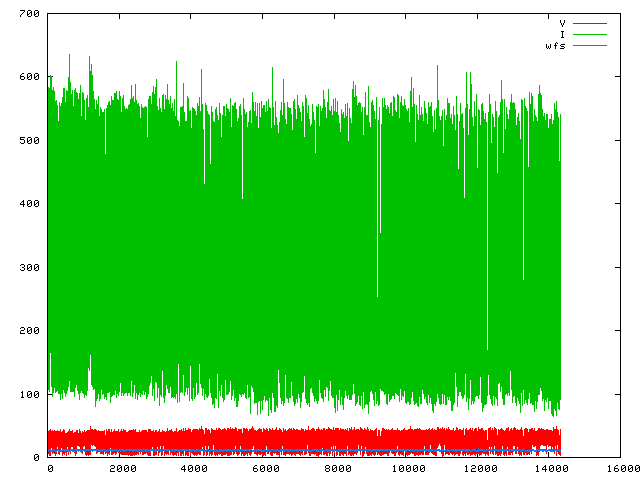

1105191340P08pulsehi236A25p1V

1105191340P08pulsehi236A25p1V

1105191340P08pulsehi236A25p1V_10000_11000

1105191340P08pulsehi236A25p1V_10000_11000

1105191340P08pulsehi236A25p1V_10400_10600

1105191340P08pulsehi236A25p1V_10400_10600

Good

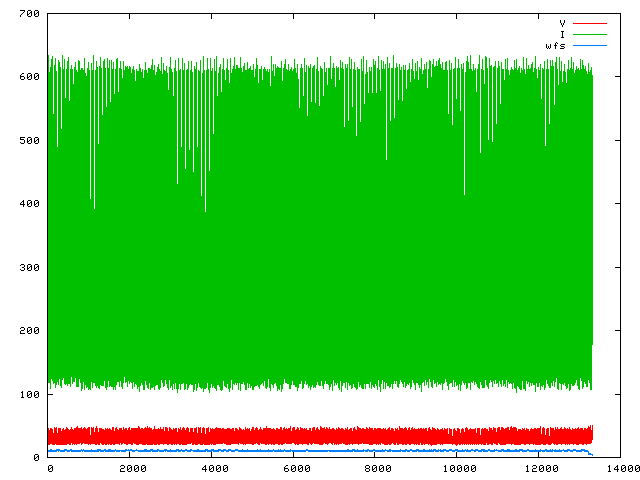

1105191340P07pulsehi240A26p6V

1105191340P07pulsehi240A26p6V

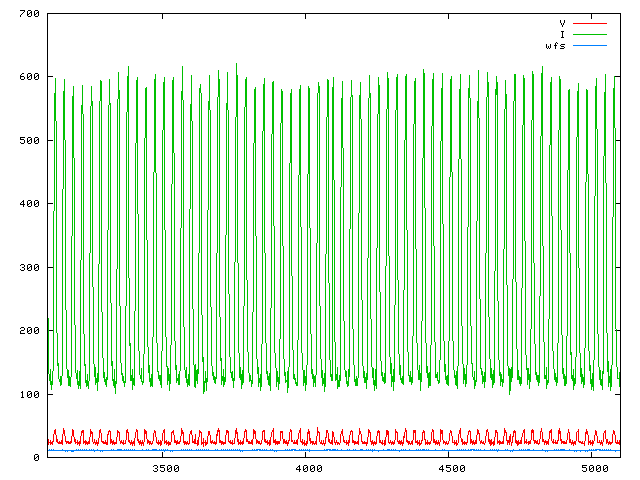

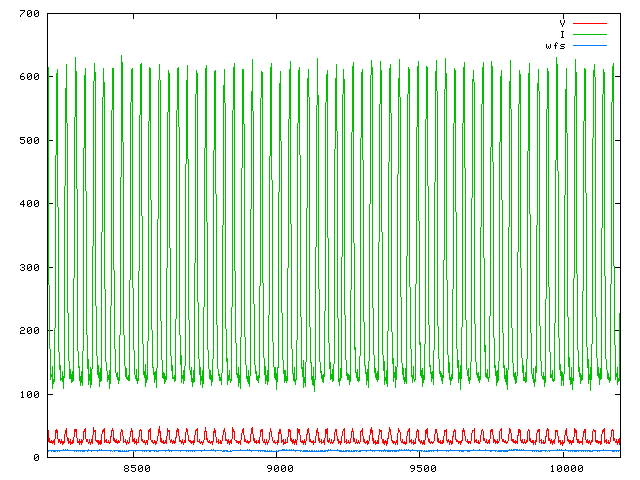

1105191340P07pulsehi240A26p6V_3100_5100

1105191340P07pulsehi240A26p6V_3100_5100

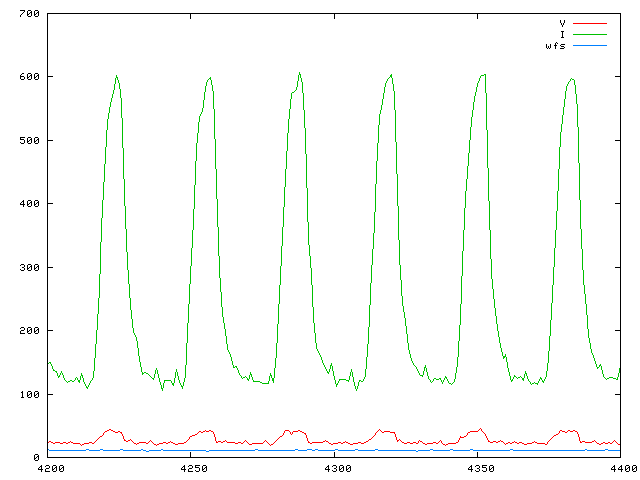

1105191340P07pulsehi240A26p6V_4200_4400

1105191340P07pulsehi240A26p6V_4200_4400

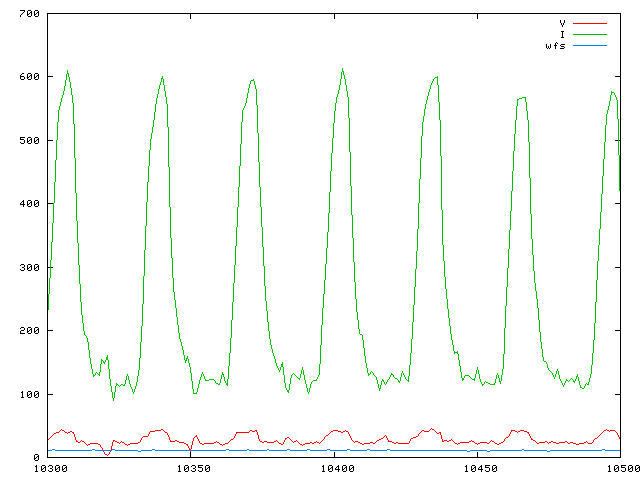

1105191340P07pulsehi240A26p6V_10300_10500

1105191340P07pulsehi240A26p6V_10300_10500

Very smooth; easy to use welding condition (however heat input unnecessarily high?)

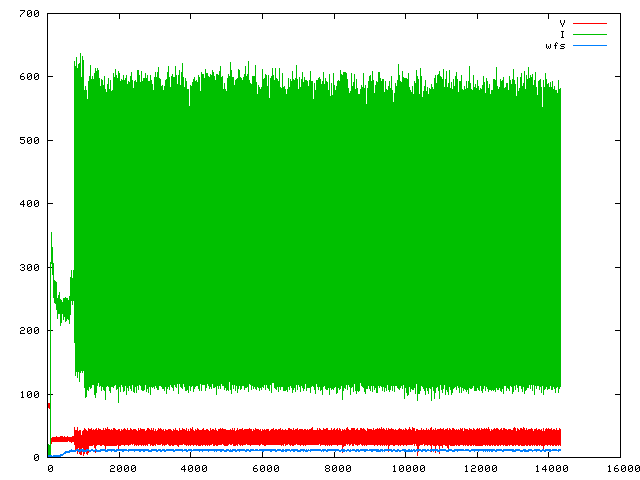

1105191340P05pulsehi253A28p4V

1105191340P05pulsehi253A28p4V

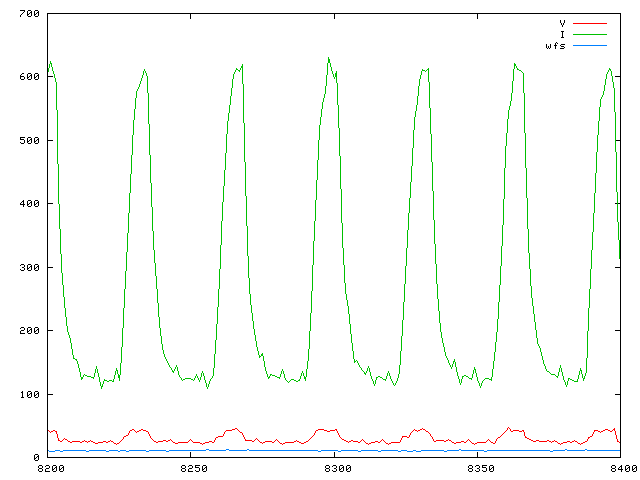

1105191340P05pulsehi253A28p4V_8200_10200

1105191340P05pulsehi253A28p4V_8200_10200

1105191340P05pulsehi253A28p4V_8200_8400

1105191340P05pulsehi253A28p4V_8200_8400

R D Smith, 26 May 2011