It was asserted that wax remaining in the casting cavities after dewax and before casting become carbon / cinder residues and affect castings with problems like blowholes.

Plausible?

The reason for wanting to know is that it affects prioritisation of how the wax-castings are optimised.

Here was my investigation and its outcome.

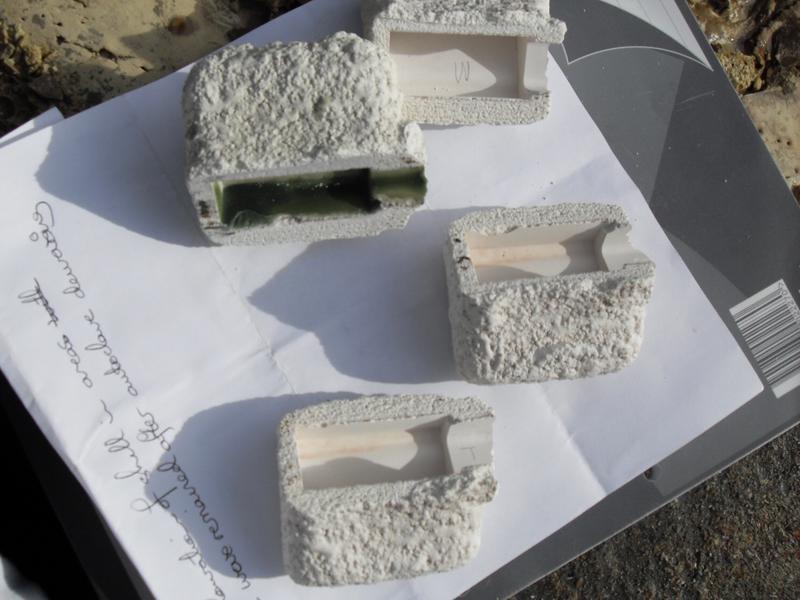

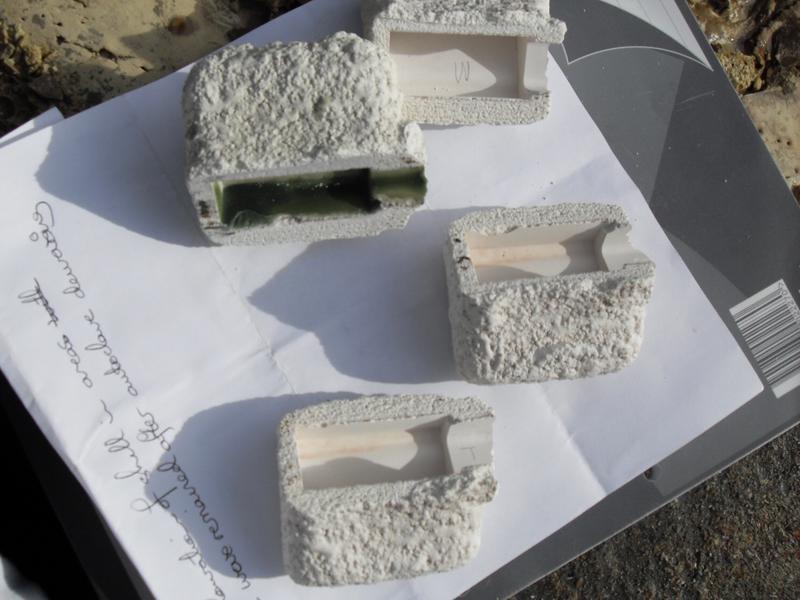

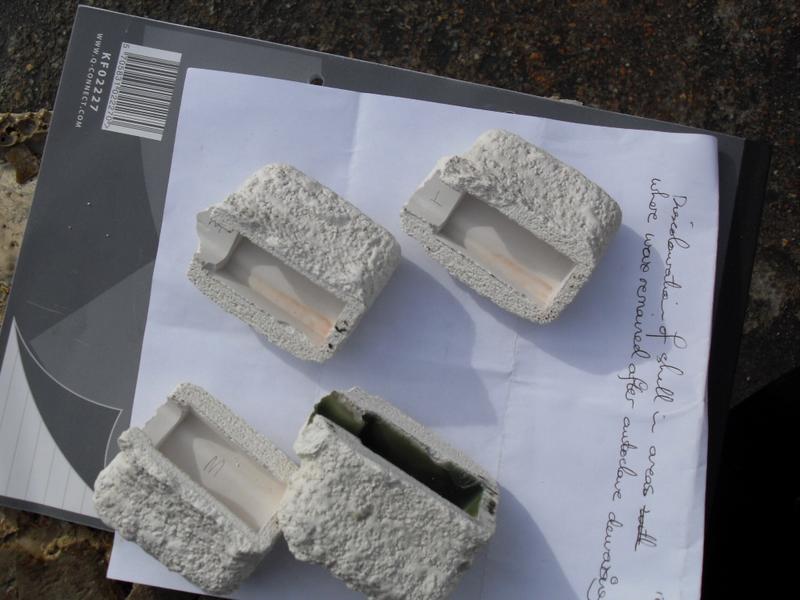

detailed explanation of the samples seen in the photograph.

Interpreting what can be seen in the photos:

There is trapped residual wax pooling at the bottom of the product casting cavity as the shell stands in the dewaxing steam autoclave.

After firing, there is no free carbon or any other residue in the casting cavity. There is a salmon-pink discolouration of the shell in the regions where the retained wax previously resided. Which seems to be sintered into the shell - it can only be disturbed by scratching away the zircon lining of the casting cavity.

The initial contention is rejected. Residual wax does not lead to carbon or cinder deposits in shells. All wax seems to be burned / oxidised away. There is no reason to think the small amount of ash sintered into the shell can affect casting quality. Inspecting product castings, there is no loss of quality in regions corresponding to where residual wax pooled.

Therefore, the original wax casting form should not be optimised for wax drain on dewax at the expense of any other optimisation which would increase casting quality.

Additional note - the supplier of the wax certifies the fired-ash content, which is around 0.010% - very low. And they explain that ash mainly originates from the Rosin content - Rosin being a substance derived from natural tree resins. So it cannot contain unusual elements or compounds in any quantity which could conceivably affect casting quality.